Hanwha Corporation

www.hanwhacorp.co.kr- 2022 Total Sales

- 3,005 In USD millions

- 2022 Total Assets

- 8,469 In USD millions

EXPERTISE

- - Global : Industrial explosives products, fireworks, domestic and overseas mining services, petrochemicals, inorganic compounds, eco–friendly energy

- - Momentum : Secondary battery production equipment, solar cell and module manufacturing equipment, display manufacturing and logistics equipment, collaborative robots, factory automation (autonomous guided vehicles, automated warehouses, logistics centers)

- - Engineering & Construction : General construction (complex development, renewable energy, including wind power and hydrogen), civil engineering, commercial and residential building, infrastructure, environmental facilities, industrial and power plants

Since Korea Explosives was established in 1952, Hanwha Corporation has been leading the domestic explosives and related industries for more than 70 years, fortifying the foundation for Hanwha Group’s growth. In November 2022, we merged with our subsidiary Hanwha Engineering & Construction and reorganized the business into three divisions: Hanwha Corporation/Global, Hanwha Corporation/Momentum and Hanwha Corporation/Engineering & Construction.

Each division will strengthen growth engines and raise its profile at home and abroad by developing high value–added technologies, entering new businesses and expanding overseas businesses. In March 2022, we acquired stakes in REC Silicon, a Norway–based U.S. polysilicon manufacturer, as we expand our business into core materials for semiconductors and secondary batteries as well as polysilicon, which is used for solar power.

-

Hanwha Corporation/Global

Hanwha Corporation/Global

-

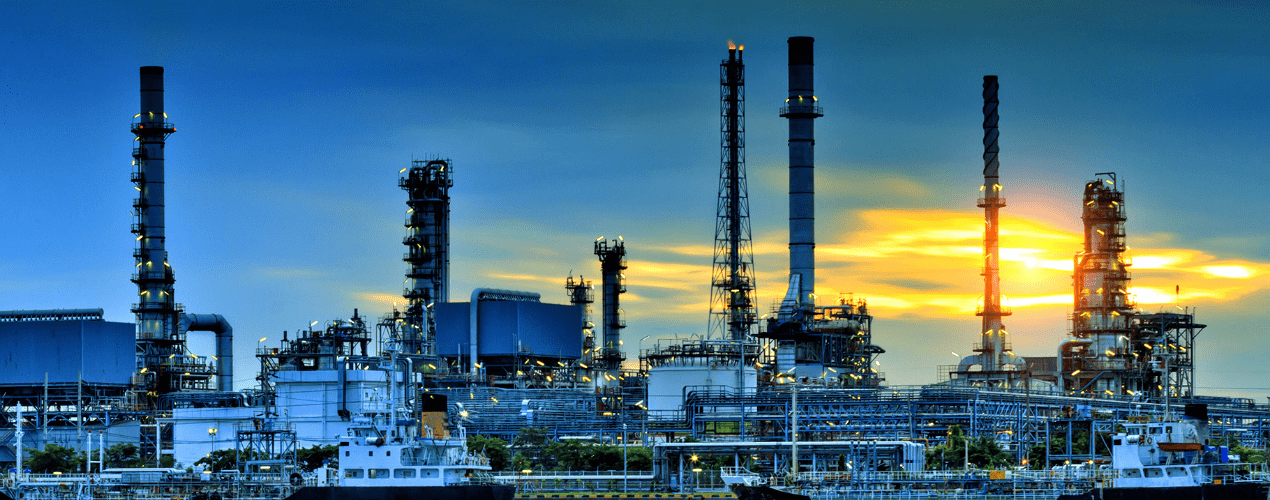

By leveraging our extensive operating synergies, business networks and more than seven decades of experience in explosives, Hanwha Corporation/Global has transitioned into chemical technology–based solutions, effectively meeting the challenges of energy and the environment.

Our industrial explosives products are essential for a range of construction and resources development. Our experience, knowledge and technology are leading domestic and overseas explosives markets with competitive and quality products supported by stable distribution networks. We also provide electronic detonators and unique blasting systems that provide customers with safe, economical and efficient blasting solutions. In addition, we operate a fireworks business that lights up the night sky at major national and regional events.

We are achieving steady revenue in trading by focusing on polymers, monomers and defense products that showcase our sales rights and expertise. Going forward, we will expand our business model into eco–friendly energy sources, such as ammonia and hydrogen.

We expect to continue efforts to localize next–generation materials, such as silicon gas, a material used for semiconductors and secondary batteries, as well as eco–friendly derivatives that help reduce global warming. By commercializing inorganic compounds, we will secure new growth engines, such as high value–added derivatives using nitric acid and a hydrogen infrastructure.

-

Hanwha Corporation/Momentum

Hanwha Corporation/Momentum

-

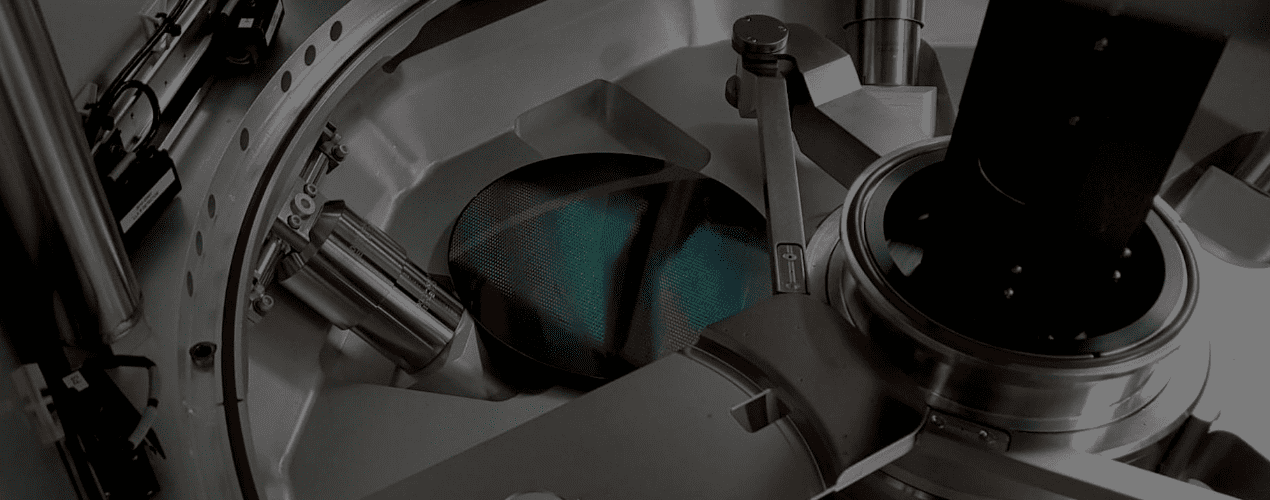

Hanwha Corporation/Momentum was established in 1953, and, today, its deep experience and cutting–edge technology leads the global machinery & equipment industry. We produce high value–added machinery & equipment while exploring new business opportunities that focus on heat treatment, vacuum deposition processing, logistics, ICT and robotics.

Both domestically and internationally, we provide market–proven turnkey solutions for battery companies that include the materials, electrodes, assembly and formation processes. We are further manufacturing specialized facilities for photovoltaic cells and modules using our vacuum deposition technology, a core technology of photovoltaic cell process equipment. Our infrared heating oven for LCD/OLED, a display manufacturing equipment, maintains the world's No. 1 market share with differentiated technology. In addition, we provide total solutions for the semiconductor industry with clean type automated logistics optimized for customer requirements.

We also lead the logistics automation industry with advanced factory and warehouse automation technology that we’ve been developing for the past 46 years. Our automation business is stronger than ever. We successfully completed the world’s first system to automate the entire tire production process. We ensure higher productivity and automated innovation by developing collaborative robots and autonomous guided vehicles for logistics centers and automated warehouses. In the renewable energy business, we are leading domestic renewable energy plant construction with differentiated construction and operational services capabilities.

With rigorous R&D and innovation, as well as development of our high value–added product portfolios and market entries overseas, Hanwha Corporation/Momentum is on track to be a global leader in machinery & equipment as well as a total engineering solutions provider.

-

-

Originally Taepyeongyang Construction, Hanwha Engineering & Construction was founded in 1967. In 2022, the company became Hanwha Corporation/Engineering & Construction, a division of Hanwha Corporation. From the start, we quickly became a global player by leveraging extensive experience in construction projects and applying new technologies and subject matter expertise across a wide range of projects, from industrial, chemical and power plants to civil engineering works, commercial buildings and more. With the goal of becoming a Green Infrastructure Developer, we are growing into a leader in building eco–friendly energy and environmental facilities as well as large–scale complex developments.

We have moved beyond constructing simple buildings to focus on complex development projects that combine residential, cultural, business, leisure, commercial and social infrastructures. The Suwon MICE Multi Complex for example, is a flagship urban development project with multifunctional buildings, including a convention center, an aquarium, a department store, a hotel and one of our FORENA residential complexes. In addition, we are creating distinctive urban spaces and multifunctional complexes, such as the northern area of Seoul Station, the eastern part of Daejeon Station, the Suseo Station Transit Center Complex and Seoul’s Jamsil Sports Complex.

In the short time since its launch in 2019, our residential brand FORENA has been established as a premium brand in the housing market. We are building landmark residential complexes in the nation’s major cities with the distinctive FORENA exterior design while applying differentiated designs and products in the interior. We believe the FORENA brand value is further burnishing our competencies in complex development projects.

-

-

Bismayah New City is a USD 10.1 billion project, the largest urban development in Iraq’s modern history, and the first overseas project of its kind developed by a South Korean company. The city will be the world's largest urban construction with infrastructure facilities that support 100,000 households, schools, government offices and roads as well as social infrastructure, such as water and sewage facilities. In 2014, we demonstrated our technological prowess by successfully building the world’s largest domed arena in the Philippines. We also built power and petrochemical plants in the Middle East and North Africa.

We’re nurturing the wind power business as a future growth engine. After building a 76MW wind farm in Yeongyang and a 25MW farm in Jeju Sumang, we are expanding to offshore business. We are leading development of the nation’s largest 400 MW offshore farm in Sinan.

Sharpening our competitive edge in hydrogen energy, we built the world’s largest industrial hydrogen fuel cell power plant and were the first to exclusively use hydrogen recycled from petrochemical manufacturing in the Daesan Industrial Complex. In addition, we are preparing for net zero by developing hydrogen production technology that uses biogas.

In environmental facilities, we rely on our core technologies, such as our self-developed PRO-MBR (Phosphate Removal Optimized Membrane BioReactor) advanced sewage treatment technology and patented technologies. By harnessing eco–friendly advanced technology, we are raising the bar for water treatment facilities from development to construction andoperation, such as the modernization project of the Daejeon sewage treatment plant, the largest private investment for a sewage treatment plant in South Korea

Hanwha Aerospace

www.hanwhaaerospace.co.kr- 2022 Total Sales

- 5,066 In USD millions

- 2022 Total Assets

- 11,963 In USD millions

EXPERTISE

- - Space : Space launch vehicle engines and system integration, satellite services (communications, observation)

- - Aerospace : Gas turbine engines and components, aircraft components

- - Defense : Artillery systems, armored vehicles, air defense systems, unmanned ground systems, advanced ammunition, precision-guided munitions, navigation systems, lasers

- - Marine : Lithium-ion battery systems for submarines and ships, ship engines/generators

Founded in 1977, Hanwha Aerospacehas become a leading company in the aerospace industry in South Korea. Today, our products serve not only aerospace but also the defense and marine sectors.

With an unwavering focus on customer-centric quality management, technological innovation, and product competitiveness reinforced by advanced technologies, we are surging forward as a global leader in the burgeoning space and aerospace business as well as in the land, sea, and air defense industries.

-

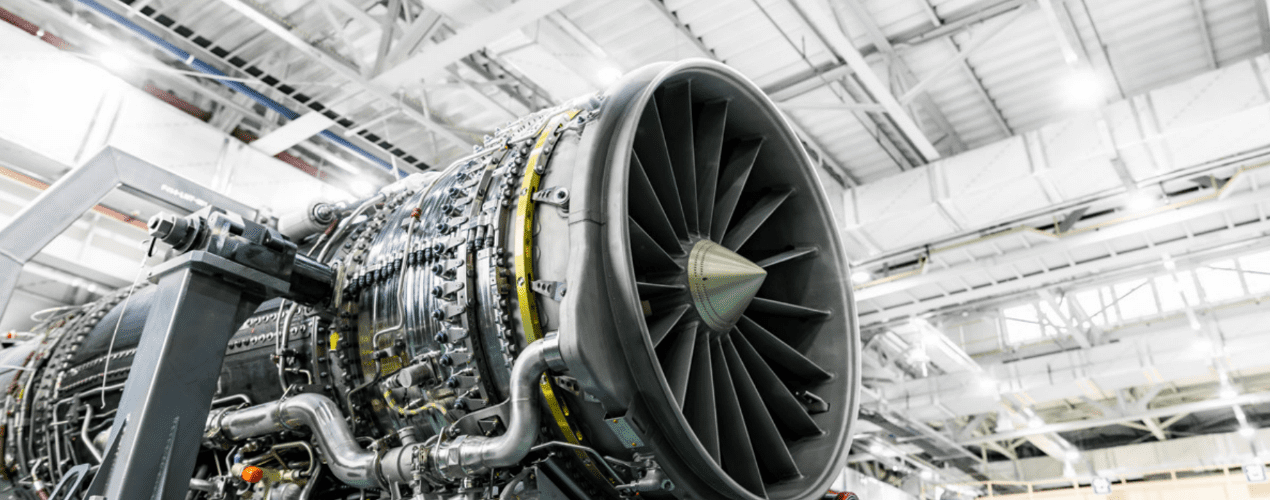

Aircraft engine manufacturing site

Aircraft engine manufacturing site

-

Our Space Division boasts unparalleled expertise in space launch vehicle engines. We have successfully produced six liquid propellant engines for Nuri, the Korea Space Launch Vehicle-II (KSLV-II), in addition to producing key components such as turbo pumps and valves, attitude control systems, and thruster test facilities. Our state-of-the-art technologies are helping advance South Korea’s space and aerospace industry. In June 2022, South Korea achieved a remarkable milestone by launching a 1-ton satellite into space using only domestic technology, the seventh country in the world to do so. The Space Division played a critical role in developing the 75-ton liquid rocket engine for Nuri, taking the country’s space technology to the next level.

In December 2022, Hanwha Aerospace was appointed system integrator for the Korea Space Launch Vehicle Program in recognition of our proven capabilities in business execution and technological expertise. Starting with Nuri’s third launch for the first half of 2023, and through a total of four additional launches by 2027, we will achieve our goal of having system integration and launch operation technologies transferred from the Korea Aerospace Research Institute. In doing so, we will be able to upgrade existing launch vehicle technology and lead efforts to create a robust space industry ecosystem. We are also committed to progressively improving our core capabilities in developing successor projects to Nuri for the next generation of launch vehicles, including localizing core components, introducing lighter-weight materials, and enhancing engine performance.

-

Advanced jet trainer/light fighter engine (F404–102)

Advanced jet trainer/light

Advanced jet trainer/light fighter engine (F404–102)

Advanced jet trainer/light

fighter engine (F404–102) The 75–ton liquid propellant engine for Nuri,

the Korea Space Launch Vehicle–II The 75–ton liquid propellant

engine for Nuri, the Korea Space

Launch Vehicle–II -

In addition to developing launch vehicles, the Space Division is focusing on building a value chain for the space industry. In 2021, we acquired a 30% stake in Satrec Initiative, a South Korean developer of core satellite technologies that support Space Eye-T, a constellation of the world’s highest-resolution Earth observation imaging satellites. We are also partnering to develop future businesses that will utilize satellite data. As a key supporting affiliate of Space Hub, Hanwha’s oversight venture into the space industry, we are actively exploring a variety of future business opportunities that bring together our existing strengths and capabilities in the space industry.

Our Electric Propulsion System Division is growing as an eco-friendly powertrain supplier in urban air mobility (UAM), a promising area of growth in future mobility. We are developing a highly reliable electromechanical actuator for next-generation transportation as well as hydrogen fuel cell systems for UAM. By 2025, we aim to take the lead in creating an ecosystem for the domestic UAM market by securing core technologies for hydrogen fuel cells for aviation. Leveraging our lithium-ion battery systems for submarines, we are also developing a next-generation energy storage system (ESS) optimized for general ships, which will allow us to lead in the eco-friendly ship market.

-

K10 Ammunition Resupply Vehicle and K9 Thunder SPH artillery system

K10 Ammunition Resupply Vehicle and K9 Thunder SPH artillery system

-

Since the launch of our gas turbine engine business in 1979, our Aerospace Division Chairman’s Message Future Vision Business Highlights Hanwha Overview Hanwha Businesses Sustainability 057 has produced more than 9,000 engines over the past four decades. The engines have powered a range of fighter jets, such as the F-15K and T-50 advanced jet trainer, localized engines for South Korea’s domestic multipurpose helicopter Surion, and provided engines for naval flagship vessels. We also provide airframe and gas turbine engine solutions to domestic and international markets. In technological collaboration with GE, the Division is taking the lead in developing an integrated engine for the KF-21, a next-generation South Korean fighter jet, while localizing its key components. As the nation’s major supplier of aviation parts, we have provided core components such as flight control actuators and hydraulic/fuel control systems for the KT-1, T-50, and Surion. In the KF-21 project, we are further enhancing our technical expertise by exploring new areas, such as landing gear.

Building on our extensive expertise in aircraft engine technology, the Engine Parts Division has become a key partner of global aviation engine companies such as GE, Rolls-Royce, and Pratt & Whitney, which has strengthened our competitive stance around the globe. We continue to expand our global network, including in overseas production subsidiaries. In 2016, we entered into a joint venture with Pratt & Whitney to operate a Singaporean manufacturing company as well as a Risk and Revenue Sharing Partnership (RSP) designed to co-build the next-generation aircraft engine. In 2017, we established a production base in Vietnam to improve our cost competitiveness and increase production capacity. In 2019, we acquired EDAC Technologies, a US aircraft engine component manufacturer, and launched Hanwha Aerospace USA to expand our product portfolio and leverage high-end processing technology.

At our LS (Land Systems) Division, we develop state-of-the-art weapons systems designed to produce sustained growth in all arenas of the defense industry, including artillery, armored vehicles, air defense, amphibious systems, and manned-unmanned teaming systems.

In artillery systems, we developed the K9 self-propelled howitzer (SPH) based on our experience of producing K55 SPHs. Our world-class K9 Thunder SPH artillery system is recognized for excellent firepower, maneuverability, and survivability. Known for high-quality standards, the K9 is exported to eight countries worldwide and holds the largest market share in the global SPH market. Our continuous improvements in performance have expanded its entry into advanced defense markets, such as the UK and the US. The K10 Ammunition Resupply Vehicle, the world’s first fully operational automated ammunition support system, works in conjunction with the K9, further ramping up the speed of ammunition delivery. In addition to these systems, the Division also manufactures a variety of land-based launcher systems and naval launchers.

We are proud to offer a diverse portfolio of armored vehicles that are highly effective in Multi-Domain Operations (MDO). Key products include the 120mm self-propelled automatic mortar system, which offers superior combat distance and firepower compared to conventional mortars; seven types of specialized armored vehicle models that rely on technologies from the K200 Armored Personnel Carrier, such as the NBCRV (Nuclear Biological Chemical Reconnaissance Vehicle); and the K21, a world-class infantry fighting vehicle. We are also promoting the REDBACK, a future-ready armored vehicle, for overseas markets. In air defense systems, we are incorporating advanced technologies to develop best-in-class systems optimized to respond to and defend against various aerial attacks, bolstering the ROK military’s air defense capabilities. The Hybrid BIHO self-propelled air defense system, recognized as highly effective, leverages artillery and missile system strengths to intercept low-altitude infiltration targets. Our Anti-Aircraft Gun Wheeled Vehicle System (AAGW) includes low-cost highly efficient 30mm twin air defense guns and has been in use by the South Korean military since 2021.

In amphibious systems, we are currently engaged in cooperative production of the KM3, a South Korean type of amphibious bridging vehicle, which is key in providing rapid mobility support for the military. We are also developing our own improved ribbon bridge equipment. In addition, we are engaged in active R&D to upgrade the primary armored personnel carrier for the ROK Marine Corps, the Korean Amphibious Assault Vehicle (KAAV-II), which will replace the current KAAV model with significant advances in mobility, protection, and firepower. In manned-unmanned teaming systems, we are integrating manned and unmanned systems that will optimize mission effectiveness and reduce human casualties in future battlefield scenarios. Our emphasis on core technologies, such as artificial intelligence, remote control, and autonomous driving, has put us at the forefront of technological innovation in the military sphere. Current initiatives include developing remote unmanned K9 SPH, unmanned search vehicles, and multipurpose unmanned vehicles.

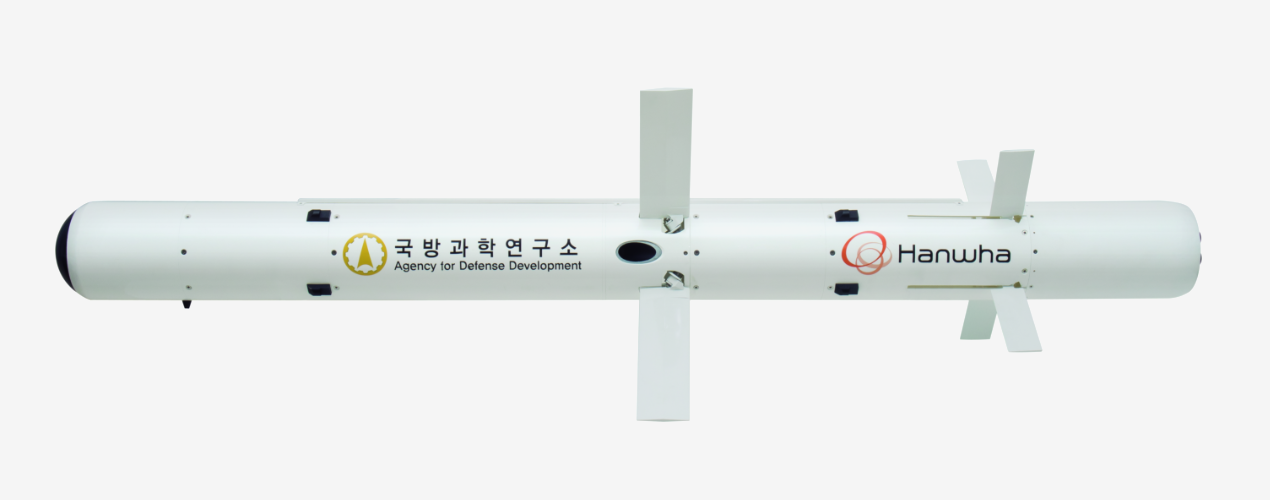

Since entering the defense industry in 1974, the PGM (Precision Guided Munition) Division has focused on global competitiveness and expanding business related to guided weapons, advanced ammunition, and lasers. In guided weapons systems, we are developing projects across land, sea, and air as we advance weapons systems from propulsion engines to integrated guidance and control systems. Our flagship product, the CHUNMOO, was the first company-led system development project in South Korea, which became fully operational in 2015, and significantly enhanced the power of the ROK Army. By maintaining advanced global quality, technology, and price competitiveness, we provide customized solutions to overseas customers. We will expand our global footprint by securing a variety of range-specific solutions.

-

-

In addition, we are prioritizing L-SAM, long-range surface-to-air missiles, and CHUNGUM, an air-launched anti-tank guided missile, carried on a LAH (Light Armored Helicopter). These are crucial pillars that support the South Korean missile defense system. Given the growing demand overseas for anti-tank guided weapons and increased need in domestic operating platforms, we are developing CHUNGUM to be compatible with ground platforms that will target international markets.

Our advanced ammunition systems offer unrivaled technology in ammunition core components, including detonators and propellants. We will participate in -guided ammunition projects to continue to sharpen our technology in ammunition systems precision and guidance. As the nation’s leader in laser technology, we are developing a future weapons system that applies high-energy laser technology while promoting localization of original technology.

At our Navigation Systems Division, we specialize in developing and manufacturing advanced navigation systems that play a critical role in advanced weapons systems. The navigation system’s advanced equipment controls a platform's movement by providing essential information on speed, position, and attitude. With high-level expertise in gyro sensors, the core technology of navigation systems, we boast unparalleled technology in this field. Navigation systems were once primarily used only in the military, such as for guided missiles and aircraft, but applications have since expanded into commercial arenas, including in drones, robots, and autonomous vehicles, highlighting the potential for this field to become a mid- to long-term growth engine.

Hanwha Aerospace acquired Hanwha Defense and Hanwha Corporation/Defense in November 2022 and April 2023, respectively. We are leveraging the expertise of each affiliate in the arenas of land, sea, air, and space technologies in order to create maximum synergy and seek sustainable growth by improving our global competitiveness. We remain dedicated to securing next-generation core technologies and strengthening quality competitiveness to become a global leader in future technology.

Hanwha Ocean

www.hanwhaocean.com- 2022 Total Sales

- 3,732 In USD millions

- 2022 Total Assets

- 9,508 In USD millions

EXPERTISE

- - Commercial Ships : LNG carriers, tankers, container ships, LPG carriers

- - Offshore Plants : Drilling rigs (drillships, jack-ups, etc.), production facilities (FLNG, FPSO, fixed platforms, etc.), offshore wind turbine installation vessels

- - Specialty Ships : Destroyers, frigates, submarines

Over the past half-century, Hanwha Ocean has emerged as a leading global company with extensive expertise and experience in the shipbuilding and offshore industry. Since its inception in October 1973, our shipyard near the Port of Okpo in South Korea’s Geoje, Gyeongsangnam-do has played a crucial role in our growth as a world-class shipbuilder. With a focus on advanced technology and innovation, we have continuously pioneered new businesses and now produce a vast range of vessels, including commercial ships, drillships, floating oil production facilities, and specialty ships, such as submarines and destroyers. We are also committed to securing new growth engines by anticipating market trends and enhancing our competitive strengths.

Newly launched as part of Hanwha Group in 2023, Hanwha Ocean will be at the forefront of building a green energy value chain, combining our existing strengths as a global leader in energy production facilities and transportation, with Hanwha’s expertise in energy and materials, such as hydrogen, wind power, LNG, and ammonia. We will also leverage Hanwha's cutting-edge green technology, such as advanced marine systems and eco-friendly energy storage system (ESS) technology, and integrate that with our ship, offshore plant, and specialty ship businesses to create new synergies and expand our markets.

-

-

Equipped with top-notch facilities that span roughly 4.9 million square meters in Geoje, including the world's largest 1-million-ton dock and 900-ton Goliath crane, Hanwha Ocean produces high-quality ships and offshore plants. We are also developing green solutions, such as energy-saving devices (ESD) and propulsion technologies that use environmentally friendly fuels, and, by automating and mechanizing the shipyard, we have improved working conditions and achieved cost savings. In addition, we are working to produce technologies that provide the latest marine and energy infrastructure solutions to our customers from cutting-edge R&D infrastructure, including a maritime defense industry research institute—the only such facility across all South Korean shipyards. With our IT-based systematized shipbuilding technology, advanced offshore plant construction capabilities, large-scale plant management capabilities, and expertise in submarine and destroyer construction technology, we offer leading services in the shipbuilding and offshore sectors as a total solutions provider.

While continually expanding our field of business globally since 2000, we have achieved numerous world-firsts: delivering the world's first and only LNG regasification vessel (LNG RV) that supplied natural gas to disaster areas in the aftermath of Hurricane Katrina in the U.S. in 2005; constructing the world's first floating LNG (FLNG) facility in 2016; delivering the world’s first LNG carrier with a full regasification system (FRS) in 2018; and delivering 15 icebreaking LNG carriers for Arctic operations in November 2019. Hanwha Ocean also delivered the world's largest 23,000 TEU container ship in 2020, among other accomplishments. These achievements were produced by strong integration and cooperation among our two plants in Korea, a global office, and nine overseas branches, as well as by our expansion in exports to global markets, and improved customer service. Building on this success, as of January 2023, we hold the third-largest backlog of ship orders in the world, measured by Compensated Gross Tonnage (CGT)[Clarksons Research].

-

Hanwha Ocean icebreaking LNG carrier

Hanwha Ocean icebreaking LNG carrier

-

Hanwha Ocean’s flagship commercial ship business leads the global market with unrivaled technology. Our LNG carriers are the world's most competitive, thanks to our expertise in LNG-related technology, including a self-developed fuel gas supply system (FGSS) and partial regasification system (PRS). Our LPG carriers, built with eco-friendly and highly efficient technology, have set the industry’s global standards for accurate delivery and first-rate technological prowess. With about a 20% share, Hanwha Ocean ranks No. 1 in the world for VLCCs (Very Large Crude Oil Carriers) in operation. We have also built special tankers, such as shuttle tankers and oil carriers with differentiated technology. All of our tankers are next-generation eco-friendly vessels, featuring high-efficiency engines and the latest fuel-saving technology, which meet environmental regulations set by the International Maritime Organization (IMO). Since winning an order from Maersk in 2011 for 20 Triple-E class container ships with a capacity of 18,000 TEU, our ongoing technological advancements have given us the competitive edge to lead in the eco-friendly mega-container ship market.

In the field of offshore plants, we specialize in developing and producing advanced facilities and platforms optimized for harsh marine environments by using the best available production systems and facilities. Combining our expertise in LNG production, refining, and transportation, we built and delivered the world's first FLNG facility for Petronas. We provide one-stop solutions for top and bottom structures, including Floating Production, Storage, and Offloading (FPSO) and fixed platforms as well as produce cutting-edge drilling equipment for offshore and deep-sea oil exploration, such as drillships and rigs, which open up new possibilities in related industries.

-

Transocean drillship

Transocean drillship

-

To ensure a dominant position in the fast-growing offshore wind power market, we are actively pursuing the ultra-large wind turbine installation vessel (WTIV) business. In 2022, we secured a WTIV order from Monaco-based Eneti and installed our cutting-edge eco-friendly technologies, such as the self-developed smart ship system (DS4). The vessel has received positive customer feedback and continues to generate interest from those within the industry.

Specialty ships in advanced defense technology represent another major business area in which Hanwha Ocean holds unrivaled experience. Our history of submarine construction goes hand in hand with that of South Korea’s navy. After first building KSS-I (Korea Submarine-I) class submarines in the late 1980s, we subsequently participated in the KSS-II (Korea Submarine-II) project. In August 2021, Hanwha Ocean became the first company in South Korea to fully design, build, and deliver a submarine: the KSS-III (Korea Submarine-III) Dosan Ahn Chang-ho, which solidified our position in the field. With the ability to develop core submarine technologies, we were able to advance into the global market. In 2004, we successfully completed an Indonesian submarine overhaul project, and, in 2021, won the bid to deliver three new Indonesian navy submarines, making South Korea the world’s fifth largest submarine exporter. We have also played a pivotal role in upgrading the South Korean navy’s combat vessels by delivering two next-generation vessels with advanced technologies, FFX (Future Frigate eXperimental) Batch II frigates. Capitalizing on this experience, we have expanded internationally, delivering frigates to the Bangladesh navy and the Royal Thai navy, and provided logistics support ships to the United Kingdom and Norway. With the strongest track record as a shipbuilder in South Korea’s defense sector, and by leveraging its know-how and technological capabilities, Hanwha Ocean is on course to become a dominant player in the global maritime defense industry.

Moving forward, Hanwha Ocean is committed to utilizing advanced technology to provide solutions that will drive change and help the world fight climate change. We will work to usher in a new era for the industry by extending the reach of digital transformation into our shipyards, bringing to life smart yards, and delivering low-and zero-carbon solutions that can power the energy transition. In addition to improving our competitive edge in the LNG carrier business, we will pioneer future markets and help realize carbon neutrality by developing eco-friendly vessels equipped with green ship solutions, such as high manganese steel tanks and rotor sails; creating new types of ships to carry LCO2 (liquified CO2), LH2 (liquified H2), and LNH3 (liquified NH3); developing zero-emission ships; and leading the market for next-generation offshore wind turbine installation vessels. We will also continue to strengthen our core competitiveness by creating autonomous cargo ships that run on smart ship platforms with autonomous navigation, among other innovations. By focusing on eco-friendly and smart digital technology, Hanwha Ocean will deliver new value to its customers and be at the forefront of transforming the ocean and marine energy ecosystem to one that is sustainable for future generations.

Hanwha Systems

www.hanwhasystems.com- 2022 Total Sales

- 1,694 In USD millions

- 2022 Total Assets

- 2,423 In USD millions

EXPERTISE

- - Defense : ISR (Intelligence, Surveillance, Reconnaissance), C5I (Command, Control, Communication, Computer, Cyber and Intelligence), land and naval systems, aerospace, ILS (Integrated Logistics Support)

- - ICT : System integration, application management, infrastructure management, cloud management, system management, IT solutions, blockchain, AI (Artificial Intelligence), cloud computing, smart factory

- - New Business : UAM (Urban Air Mobility), electronically steerable antenna

As a global total solutions company, Hanwha Systems provides differentiated smart technologies by leveraging synergies with advanced defense electronics and future–ready ICT technologies. In addition to our world–class expertise in defense electronics, we also provide state–of–the–art IT services, such as AI, big data, blockchain, cloud services and more, to lead digital innovation across a range of industries.

-

KF–21 AESA radar

KF–21 AESA radar

-

Our Defense Division, recognized for significantly advancing South Korea’s military defense capabilities, has been exporting defense technologies, such as ISR, C5I, land and naval systems, aerospace and ILS. In 2022, highlighting our global expansion, we signed an agreement with the United Arab Emirates to export USD 1.03 billion worth of multifunctional radars (MFRs) to be mounted on the Cheongung–II MSAM (Medium–Range Surface–to–Air Missile) Systems.

In surveillance and reconnaissance systems, we provide electro–optical systems, such as infrared detection and tracking devices, while also participating in defense programs to develop advanced radars such as KF–21 AESA (Active Electronically Scanned Array) radar and L–SAM MFR (Long–Range Surface–to–Air Missile Multi–Function Radar). We’re also developing new multifunction radars to complement our next–generation combat systems, such as FFX Batch–III.

Our C5I (Command, Control, Communication, Computer, Cyber and Intelligence) business has successfully developed and delivered the next–generation TICN (Tactical Information Communication Network) as well as the next–generation MILSATCOM (Military Satellite Communication) Systems. As a dominant player in this field, we intend to further develop C5I and tactical information communications systems that provide hyperconnected, intelligent solutions.

In the naval arena, our main product is CMS (Combat Management System), which combines various sensors, weapons and communications systems to act as the “brain” for naval vessels. We utilized our in–house technologies to locally develop and manufacture these systems. Currently, we are the sole supplier of CMS for the ROK (Republic of Korea) Navy. Our CMS is used for a full range of ROK Navy vessels, including surface and underwater vessels, fast battleships, large amphibious assault ships, training ships, destroyers, frigates and submarines.

In aerospace, Hanwha Systems provides electro–optics and infrared payloads for mid–to–large–sized satellites as well as synthetic aperture radar (SAR) payloads for military reconnaissance satellites. That gives the military forces near real–time surveillance and high–resolution images of the Korean Peninsula and surrounding areas. These cutting–edge technologies define us as a true leader in the new space era. We’re also developing core equipment for the KF–21 Boramae fighter jet by leveraging our technologies in developing mission sensors, mission computers, displays and survival systems.

In land systems, Hanwha Systems provides the integrated electronics platform system (IEPS), which is called a “brain” that can maneuver and fire air defense weapons systems while maximizing capabilities in ground battlefields. We are developing a platform that enhances each combatant’s mission performance by applying advanced technologies to individual gears as well as to remote control solutions, a key to operating unmanned ground systems. To help the Army maximize fighting strengths, we will offer hyperconnected, automated, intelligent and unmanned land systems solutions.

-

ICT big data center

ICT big data center

-

Our ICT Division is delivering customized solutions to meet specific customer needs in various industries by utilizing core technologies of the Fourth Industrial Revolution. Hanwha Systems is demonstrating differentiated capabilities not only for cloud–based data analysis but also for smart factories and financial IT systems, powered by big data, the cloud, ITO/IDC and business–specific solutions. We will lead the digital transformation of the industry by diversifying our business into blockchain and metaverse technologies using our advanced ICT services tailored for different sectors.

-

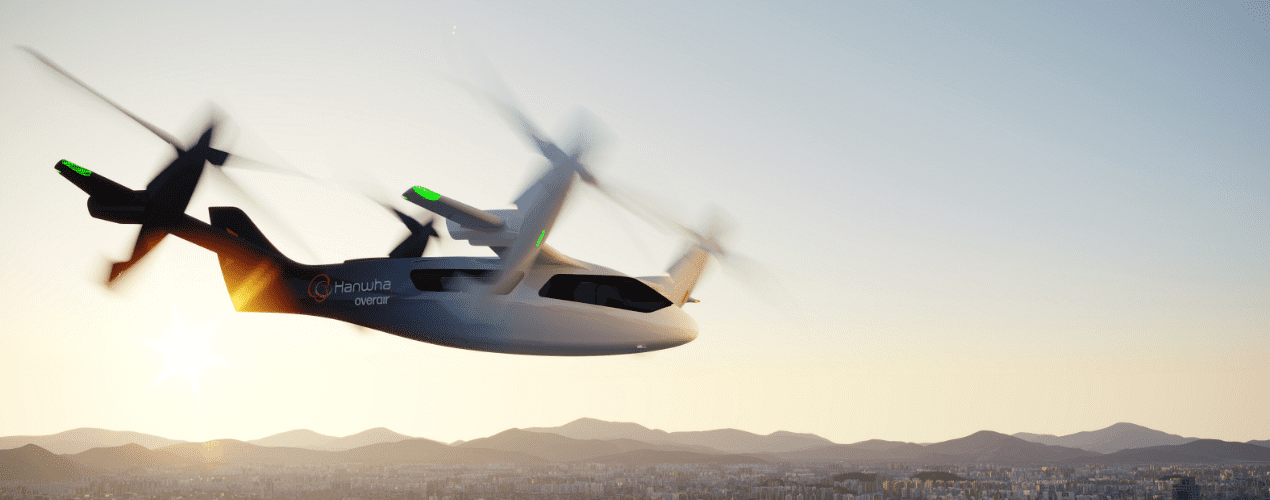

Butterfly, a UAM vehicle

Butterfly, a UAM vehicle

-

In addition, we are securing future growth engines by investing in overseas companies with advanced technology. For example, in partnership with Overair, a US company, we are developing Butterfly, a UAM vehicle, while extensively exploring opportunities to offer total solutions for future mobility.

Through our collaboration with OneWeb, a UK company, we secured Low Earth Orbit (LEO) satellite communications technology. We also established Hanwha Phasor, which designs enterprise–grade antenna for on–the–move satellite communications, whether in flight, on land or at sea. We are expanding our business with the goal of building multilayered, hyperconnected communications systems.

By connecting all platforms on land, sea, air, space and cyber space using super–intelligence as well as hyperconnected and super–convergence technologies, Hanwha Systems will continue to grow into a global provider of defense electronics and ICT smart solutions that bring humanity a more prosperous and safer world.

Hanwha Vision

www.hanwhavision.com- 2022 Total Sales

- 776 In USD millions

- 2022 Total Assets

- 549 In USD millions

EXPERTISE

- Video surveillance solutions

Established in 1990, Hanwha Vision’s advanced video and analysis technology has propelled it into a global leader in video surveillance. By applying our experience and subject matter expertise to product development, we have created a complete line of security solutions that provide safety and comfort to our customers, from cameras and recorders to storage devices, integrated management software and accessories. Our products are designed to meet every application across a range of areas, including residential, urban and commercial facilities.

Along with our proprietary optical technology, we are ready to lead global markets with world–class optical design, manufacturing and image–processing technology, such as superior SoC (System on Chip) chipset technology, intelligent image analysis AI camera technology and cyber security platform technology. We strive to enhance customer–tailored AI solutions capabilities. We are also focusing on developing new technologies and solutions that can spearhead changes in residential and industrial paradigms while meeting customer needs, such as convergence technology for AIoT platforms and edge device technology for open platforms.

-

-

By banking on our years–long core experience and competencies, we maintain the largest share of the South Korean video surveillance market. Our plants are located in South Korea and Vietnam. With these existing sites as footholds for global sales and marketing, we rank the fifth in worldwide market share (excluding China).

Moving forward, we will further expand our global market share by focusing on ten strategic markets. We will continue to build a sustainable, high–profit business structure by advancing differentiated edge AI performance. In addition, we are focused on securing our capabilities as a solutions provider by preparing integrated solutions to industry–specific demands, such as from smart retail, smart factory and smart city, while we expand our business to cloud platform–based subscription services. Our continuous technology development and product innovation optimized for customer needs will guide us to become the world's best vision solutions company.

Hanwha Precision

Machinery

www.hanwha-pm.com

- 2022 Total Sales

- 401 In USD millions

- 2022 Total Assets

- 284 In USD millions

EXPERTISE

- Precision machinery, automation equipment, software consultation/development

A global machinery company, Hanwha Precision Machinery produced South Korea’s first chip mounter, an automated PCB assembly machine. We are leveraging our deep subject matter expertise and continuous innovation to provide a comprehensive portfolio of ultra–precision manufacturing machinery, from industrial robots, semiconductor equipment and optical equipment to integrated software solutions. A dominant leader in the domestic market, we also operate five international branches to provide worldwide sales and technical support for customers, including in China, Vietnam, India, the US and Germany.

-

-

In industrial equipment, we produce Surface Mount Technology (SMT) equipment, such as chip mounters and screen printers, as well as semiconductor post–processing equipment and display manufacturing equipment with cutting–edge precision mechatronics. We’re the top leader in SMT chip mounters and our mid–speed mounter is No. 1 in global market share and recognized for best–in–class technology and performance. We are increasing growth by providing differentiated manufacturing solutions to large–scale customers by expanding our product lineup from mid–speed to high–speed machines.

Our R&D focuses on operational solutions, such as automated control of smart factory equipment and prevention of machine failures. Our consistent efforts have developed differentiated technologies for production planning, automated model changes, remote control, predictive prevention and predictive maintenance. We will secure solutions for intelligent equipment and highly multifunctional future–ready manufacturing equipment solutions by enhancing software solutions.

In semiconductor equipment, we developed die bonders and flip chip bonders, key equipment for the packaging process, which we provide to leading semiconductor companies at home and abroad. To meet the industry’s need to overcome the limitations of the front–end process with packaging technology for the back–end process, we continue to develop next–generation semiconductor assembly solutions. Our display manufacturing equipment is speeding entry into the next–generation Mini/Micro LED display market by leveraging our high–productivity SMT equipment technology and high–precision semiconductor post–processing equipment technology.

-

HM520 NEO, high–speed SMT chip mounter

HM520 NEO, high–speed SMT chip mounter

for a smart solution HM520 NEO, high–speed SMT chip mounter for a smart solution -

Building on our expertise and improved technology over 50 years, our machine tools business commands a market technical advantage because we produced South Korea’s first multitasking automated lathes and turret–type lathes. Our machine tools are custom–built to meet customer feature requirements and production lines. That has led us to capture the largest market share in CNC automated lathes in South Korea and to enter new markets worldwide.

As a leading global precision machinery company, we will continue to provide customers with a variety of advanced manufacturing equipment and solutions. In the mid– to long–term, we will transform into a manufacturing solutions specialist that provides optimal solutions for the manufacturing industry.