Hanwha Solutions

www.hanwhasolutions.com- 2022 Total Sales

- 10,576 In USD millions

- 2022 Total Assets

- 18,810 In USD millions

EXPERTISE

- - Chemicals : PE, PVC, CA, TDI, hydrogen tanks

- - Qcells : Solar cells & modules, energy systems solutions, downstream activities, retail energy

- - Insight : Renewable energy, city and smart industrial complex development (RE100, logistics, data center, etc.) premium real estate and content development

- - Q ENERGY : Green-field and project development, construction and operation of green power plants – photovoltaics and on- and offshore wind power, energy storage and green hydrogen

Hanwha Solutions provides a range of solutions in several fields through differentiated technology and innovation. We are growing as a global leader by responding to climate change with smart eco–friendly energy solutions and customer–focused materials. We are committed to enriching the future with sustainable solutions for all.

-

-

Established in 1965, Chemical Division is a total solutions chemical company with streamlined production systems that offer Polyolefin (PO), Polyvinyl Chloride (PVC), Chlor–Alkali (CA) and Toluene Diisocyanate (TDI). As South Korea’s leading petrochemical company, we dominate the nation’s industry with high–quality PVC, CA and linear low–density polyethylene (LLDPE) that we offer at competitive prices. We are growing into a global green company by increasing product value, enhancing cost competitiveness and developing eco–friendly products.

In the PO business, we succeeded in producing LPDE for the first time in South Korea in 1972, and once again, in 1985, we were the nation’s first to start producing high–density ethylene vinyl acetate (EVA) and developed the nation's first wire and cable resin for power transmissions and distribution cables. We now produce adhesives for hygiene products and hydrogenated hydrocarbon resins.

Beginning with South Korea’s first successful PVC production in 1966, our PVC business localized production of chlorinated polyvinyl chloride (CPVC) in 2016, improving the quality of our PVC. In 2014, we developed ECO–DEHCH, a premium eco–friendly plasticizer, another first in the nation. We are moving to expand our CA business in the global market while holding South Korea’s No. 1 market share in producing chlorine and caustic soda. In the TDI business, we are increasing global competitiveness in the polyurethane business by localizing high–purity XDI, a raw material used for high–refractive lenses, as we were the second to develop the technology. We obtained three New Technology Certifications from the Korean Agency for Technology Standards for CPVC, ECO–DEHCH and XDI.

We continue to improve production efficiency and cost competitiveness while meeting growing demand for our products around the world with production bases in China, Thailand and Saudi Arabia. Our PVC plant, completed in 2011 in Ningbo city in China’s Zhejiang province, is producing 360,000 tons of PVC each year with continuous improvements in the production process. In Bang Phli, Thailand, we built an alkali soluble resin plant with an annual production capacity of 17,000 tons. This facility serves as an important operational base as we expand into other Southeast Asia markets. In 2009, we signed a joint venture contract with International Polymers Company (IPC) a private petrochemical company in Saudi Arabia. In 2015, we achieved cost reductions and economies of scale as our joint venture with International Polymers Company (IPC) began to produce EVA and LDPE.

At the same time, our R&D Center is focusing on strengthening the competitiveness of existing businesses and advancing into new technologies. We partnered with three universities to set up research centers, including the Institute of Chemical Processes at Seoul National University, Yonsei–Hanwha Chemical Innovation Technology Center and the KAIST–Hanwha Chemical Future Technology Research Center. This significantly supported our commitment to top quality while accelerating the pace of innovation in developing high value–added and eco–friendly products.

In addition, we are building a plant to produce high–purity cresol using our proprietary eco–friendly process and adsorption technology for gas separation. The plant is slated to begin operating in 2023. We plan to increase value in the industry by developing high–performance super engineering plastics such as PEKK (polyetherketoneketone) and specialty phthalic anhydride, which are used in carbon fiber composites for the aerospace industry, implants for the human body and high–performance small electronics components.

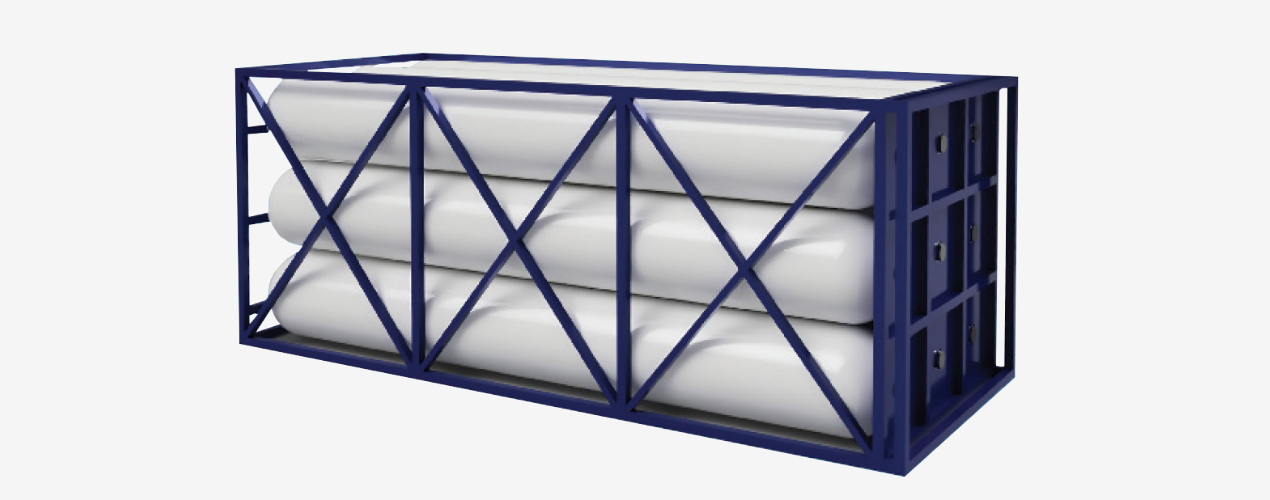

We are moving toward a circular economy system so decomposed plastic wastes can be recycled into naphtha, the raw material for petrochemical products, through carbon dioxide conversion. Our rPE material, made from recycled polyethylene sourced from waste plastic, has earned GRS certification, demonstrating our commitment to eco-friendly materials. This is part of our commitment to building a better environment for a better future. We established the Hydrogen Technology R&D Center to secure core technologies to respond to climate change and advance the net zero initiative. Through collaborative efforts with research institutes at home and abroad, we are focused on developing commercial–hydrogen production via water electrolysis. We are now poised to become a leading global company in the hydrogen energy market.

We’ve also helped to commercialize our hydrogen fuel cell technology by developing a hydrogen tank that uses an ultra–light composite material made of carbon fiber wrapped in high–strength plastic liner. Our specialized lightweight composite material technology offers manufacturing advantages, from small hydrogen tanks for drones to extra–large ones for hydrogen transportation and storage. In addition, we are accelerating expansion of our green hydrogen business through the acquisition of Cimarron, a US startup that possesses the world’s best high–pressure tank technology.

Chemical Division is strategically providing materials and solutions to help solve the issues we face today. We aim to build a diversified and sustainable business structure to work toward this goal. While sharpening competitiveness by advancing the petrochemical business, we will actively respond to paradigm shifts, such as the move toward carbon neutrality, as we develop next–generation new businesses for energy storage and efficiency as well as electrical, electronics and functional materials.

-

-

Qcells Division is a complete energy solutions provider worldwide. With cutting–edge technology and excellent quality, we are leading the global solar industry by providing the midstream of cells and modules to downstream solar solutions through ESS (Energy Storage System), power plants and energy retail. We operate manufacturing facilities in China, Malaysia, South Korea and the US. Our R&D headquarters is located in Thalheim, Germany and our R&D networks across China, Malaysia and South Korea collaborate to lead solar technology worldwide.

We are expanding cell and module plants at home and abroad. As of 2022, our annual cell production capacity is 10 GW and module production capacity is 12.4 GW. In the US, our large-scale expansion investments will result in a total module capacity of 8.4 GW by the end of 2023, giving us the largest capacity for silicon cell-based modules in North America. Electricity generated by that capacity will be able to power about 1.3 million homes for a year.

Our US solar production line will utilize polysilicon sourced from REC Silicon, a Norway–based US clean polysilicon manufacturer acquired by Hanwha Solutions. Beginning in 2024, our new plant will be fully operational, making us the only company in North America with a complete five-stage value chain production line that spans polysilicon to finished modules.

-

Finsterwalde Solar Park, Brandenburg, Germany

Finsterwalde Solar Park, Brandenburg, Germany

-

An experienced partner to clients across the value chain of renewable energy downstream projects, Q ENERGY Division provides holistic green energy solutions for renewable power plants in Europe. Headquartered in Berlin, Germany, Q ENERGY Division is comprised of the holding company Q ENERGY Solutions SE and two subsidiaries, Q ENERGY Europe GmbH (Berlin) and Q ENERGY France SAS (Avignon).

We offer more than 20 years of experience and more than 2 GW of successfully completed renewable energy assets. We operate an active development pipeline of approximately 14 GW of green energy projects in Spain, Portugal, France, Germany, the Netherlands, Italy, and the UK. Our portfolio covers photovoltaic and onshore and offshore wind power as well as large-scale energy storage projects. We are also planning green hydrogen projects. We provide expertise along the entire value chain of green energy projects: from green-field development, engineering, procurement, and construction (EPC) to operations and maintenance (O&M) and creating value for green energy investors to operating as an independent power producer (IPP).

To help propel Hanwha’s growth, we combine the strength of a global player with the reliability of a trusted local partner. We aim to create value for communities and landowners, project developers and green energy professionals, investors and off-takers as well as for our employees and society.

-

-

Since it was established in 2001,Hanwha Solutions Insight Division has been recognized as the leading private developer of high–tech industrial complexes. By merging into Hanwha Solutions in 2021, we set a new foundation for enhancing business competencies and maximizing management efficiency. In January 2022, we renamed our division Insight Division from the City Development Division, while integrating Qcells Division’s Korea Green Energy Solution business and Hanwha Galleria’s premium lifestyle business. After reorganization, we are currently providing differentiated solutions through comprehensive development and financing for projects such as cities, smart green industrial complexes, renewable energy, premium real estate and premium content.

By leveraging the experience and knowledge gained from developing high–tech industrial complexes, the City Development Business offers regional development models that provide forward–looking convergence and helps to revitalize local economies. With our success in Daedeok Techno Valley, additional projects followed, such as the Asan Techno Valley project, the Seosan Techno Valley project, the Gimhae Techno Valley project, the Gyeonggi Hwaseong Bio Valley project and Yongin Techno Valley. We are now following up with projects such as Anseong Techno Valley, Seoochang Techno Valley, a 2nd Yongin Techno Valley as well as Hwaseong H–Techno Valley, Ulsan KTX Station Area Complex, Changwon Pungho–Jangcheon Urban Development and Anseong Smart Logistics Center Development. We will continue to develop large–scale complexes that contribute to local economies by improving the industrial environment, attracting companies and creating jobs.

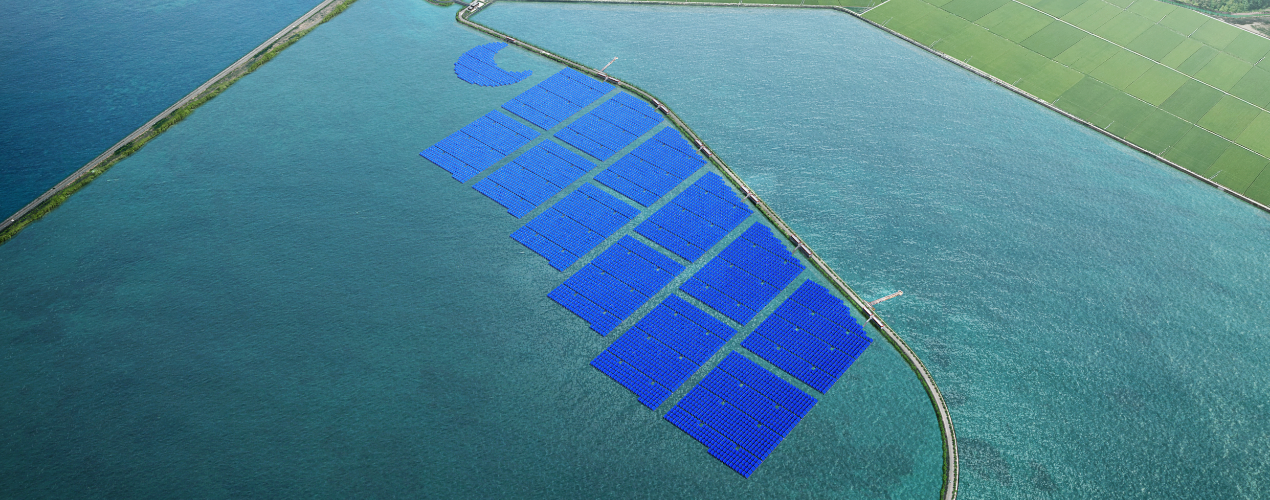

With the nation’s highest EPC (Engineering · Procurement · Construction) capabilities, our Energy Solution business presents an eco–friendly total energy solution that develops, invests in and constructs solar power while helping to achieve the goals of RE100, a nonprofit global renewable energy initiative. We are growing into South Korea’s No. 1 energy supplier with utility–level EPC business, such as the nation’s largest scale Hapcheon floating solar power plant, Goheung floating solar power plants, Taean Anmyeon Clean Energy as well as domestic salt farm parallel solar power system development. We will contribute to achieving RE100 and revitalizing local economies by developing business models that include local residents.

In the Premium Lifestyle business, we are an integrated developer that plans, develops and operates a luxury lifestyle platform focused on premium residential Gimhae Techno Valley Jade Garden and recreational facilities. After acquiring the transfer of business rights from Hanwha Hotels & Resorts in 2022, we have begun the process of renewing Jade Palace, the prestigious membership golf clubs in Chuncheon and Jade Garden. We are also developing a nearby private villa complex. In addition, we are promoting various kinds of premium development projects, such as vacation homes, private villas and residences in downtown areas and resorts at home and abroad, including luxury condos in Niseko, Japan's well–known ski resort, scheduled to open in 2023.

Moving forward, the Insight Division will focus capabilities on ongoing projects for urban development, the Energy Solution salt farm parallel solar power development and Niseko condos and Jade Villas. We plan to continually discover new businesses to secure mid– to long–term growth engines.

Hanwha Energy

hec.hanwha.co.kr- 2022 Total Sales

- 3,042 In USD millions

- 2022 Total Assets

- 8,934 In USD millions

EXPERTISE

- Cogeneration, renewable energy development, energy solutions development

Beginning with a cogeneration business in 2007, Hanwha Energy has diversified its business portfolio—including with solar power, ESS and LNG—to evolve into a retail energy business that offers a comprehensive set of energy solutions. Our advanced technology is at the core of who we are and how we can develop eco–friendly, highly efficient global energy markets with a forward–looking global energy model.

-

Oberon 1A solar power plant in Texas, US

Oberon 1A solar power plant in Texas, US

-

We operate cogeneration plants to provide a stable supply of high–quality electricity and ultra–high–pressure steam to companies in national industrial complexes across South Korea. By providing readily available power, our plants improve the competitive advantage of our off–takers. Our energy solutions consistently comply with South Korean government requirements for energy efficiency and the reduction of greenhouse gas emissions. Our relentless pursuit of advances in technology continually improves our existing solutions while we also seek new ones.

To build sustainable growth, we are diversifying and building businesses overseas in solar power generation, retail energy and more. We also operate solar power plants in the US, Mexico, Japan, Vietnam, Malaysia and India, and are building additional solar power plants in Spain and Italy. In the US, we are the first South Korean company to successfully implement a business model that links solar power generation with a retail energy business. In Spain, we are operating retail solar energy and distributed energy solutions businesses for business and consumer customers. We are also developing solar projects in Australia. Since our entry into the solar power generation and retail energy markets, we are expanding into distributed energy solutions services.

-

-

At the same time, we are actively promoting an energy solutions business that suits each value chain of the electric power industry based on ESS. We are conducting solar energy–connected ESS businesses in the US and Mexico, and we plan to steadily expand solar businesses, beginning with ESS operation for frequency regulation (FR) in Ireland.

We are also pursuing the clean energy source of LNG as we look to future growth engines and new opportunities. In South Korea, we are building a plant in Tongyeong city—a 1GW LNG power plant. Once complete, we will supply the LNG needed to power the plant and launch LNG terminal rental businesses. Overseas, we’re entering the gas–to–power market in Vietnam. To this end, we’ve formed a Hydrogen fuel cell power plant Yeosu cogeneration plant consortium with Korea Gas Corporation and Korea Southern Power Company to build LNG plants and LNG terminal businesses in Vietnam.

We aim to become the world’s leading renewable energy developer as we strengthen profitability in our cogeneration business, expand LNG business and sharpen competitiveness of solar and ESS businesses. In retail energy, we will provide differentiated services based on distributed energy solutions for each region. In addition, we will develop energy conversion technology, upgrade ESS and solar power technologies and secure digital and AI–based platform capabilities. Our diversified efforts will lead us to become the No. 1 global energy solutions provider.

Hanwha Impact

www.hanwhaimpact.com- 2022 Total Sales

- 1,594 In USD millions

- 2021 Total Assets

- 4,226 In USD millions

EXPERTISE

- Investments in eco–friendly energy, digital and data technology, biotechnology, PTA

Our company name - Hanwha Impact - encapsulates our vision of "creating a positive impact on people and the planet through technological innovation that leads to a sustainable future." As an investment company, we are embarking on a new journey focused on developing eco-friendly energy solutions and fostering future innovative technologies that will help us achieve our goal of creating a sustainable planet.

Hanwha Impact seeks to create a future in which humans and nature, reality and the virtual world all coexist, supported by innovative convergent technologies in several sectors, such as eco–friendly energy, digital and data technology as well as biotechnology. Along with eco–friendly energy and purified terephthalic acid (PTA) businesses, we secure sustainable technologies with business development and open innovation based on active M&A and strategic investments.

-

-

We are strengthening competitiveness by preemptively investing in technologies and companies. Our eco–friendly energy business continues to discover technologies and to perform demonstration projects that can be applied across the value chains of the hydrogen industry. In convergent technology, the combination of biotechnology—such as genetic engineering—with data utilization technology clearly shows breakthrough progress. By harnessing such technologies, we expect to enter or grow into promising businesses that create disruptive innovations in various industries. Our key investments currently include Inari Agriculture, a plant breeding technology company with gene editing technology; Catalog Technology, a DNA–based data storage solutions provider; and Tessera Therapeutics, a genome engineering technology company.

In the meantime, Hanwha’s PTA business is a continuous profit center for the company. PTA was developed as a base material for polyester to replace natural cotton. It is now used as the primary component in many types of polyester owing to its superior resistance to heat, mechanical strength, water resistance, wear resistance and insulation compared to other products. The applications for PTA are expanding into uses other than clothing, such as PET resin, film, paint and industrial fibers. We will further strengthen our competitiveness by improving our PTA–related technologies and continuing to develop related businesses in the value chain.

Supported by our professional investment system and talent, we will expand investments in innovative technologies, businesses and companies that have a positive impact on humanity and the planet. We will create a sustainable future by developing technologies that accelerate the transition to a carbon neutral and eco–friendly energy society as we invest in forward–looking convergence technologies, such as biotechnology, AI and next–generation computing.

Hanwha Power

Systems

www.hanwhapowersystems.co.kr

- 2022 Total Sales

- 228 In USD millions

- 2022 Total Assets

- 302 In USD millions

EXPERTISE

- Industrial compressors, power generation solutions

Established in 1977, Hanwha Power Systems launched an energy equipment business in 1997 by building on its reliable technology and deep experience in gas turbine engines. Since then, we’ve become a global powerhouse and have delivered more than 6,500 units of air and gas compressors worldwide. In 2017, we relaunched as an independent company and have achieved an operating surplus for four consecutive years through 2021, setting the foundation for stable growth. In October 2022, we were acquired as a subsidiary of Hanwha Impact.

-

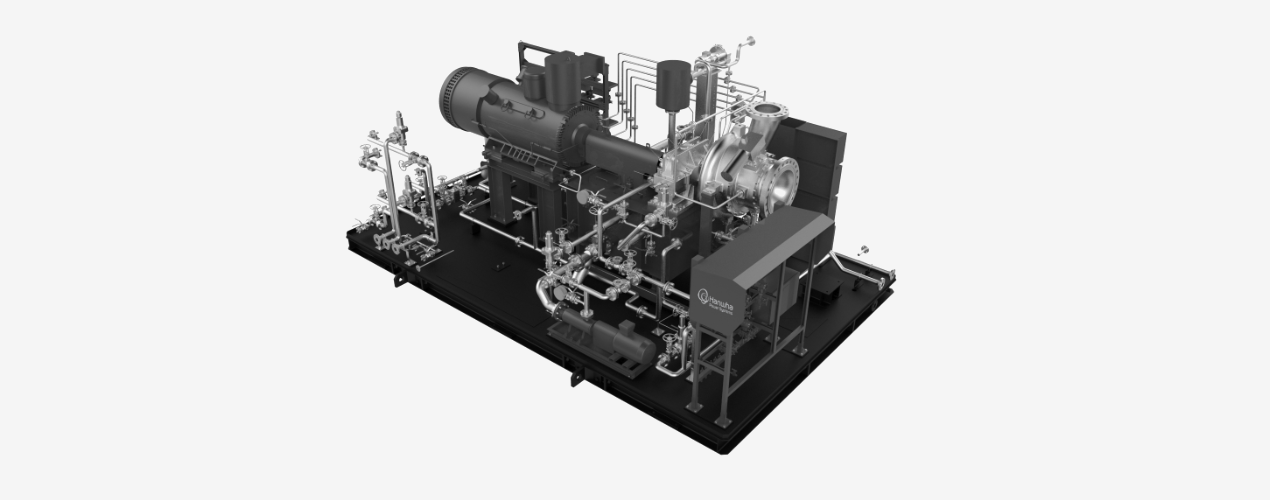

Turbo compressor for

Turbo compressor for

VRU (Vapor Recovery Unit) -

In the compressor business, we utilized our proprietary design, production and testing capabilities to develop technology–intensive products, including industrial air compressors for various manufacturing processes; fuel gas compressors for power plants; and boil–off gas compressors and expanders for LNG carriers, terminals and plants.

We won the contract to supply the world's first marine Vapor Recovery Unit (VRU) steam recovery turbo compressor. We also won the contract to provide compressors for Floating Storage Regasification Units (FSRU) and LNG carriers. These machines allowed us to demonstrate our outstanding technology in the global market. Our compressors and expanders use core components developed in–house that permit them to operate with shorter lead times and better performance. Their high efficiency is a competitive advantage for our customers. In 2021, we were awarded a Nitrogen Refrigerant System (NRS) project for a Liquefied Natural Gas Floating Storage Unit (LNG–FSU) from Daewoo Shipbuilding & Marine Engineering, which led to being selected as the standard for NRS specifications and listed on the maker list.

We continue to grow in the power generation solutions market by developing eco–friendly and high–efficiency power generation systems, such as TEG (Turbo Expander Generator) and sCO2 Power Systems (Supercritical CO2). In 2021, we successfully completed the sCO2 Power Systems development project for the US Department of Energy (DOE) and passed tests for commercialization, preemptively securing solutions that can replace existing steam turbines in the distributed power generation.

With the goal of accelerating the transition to clean energy across our society and industry, we acquired hydrogen combustion technology companies. We now provide customers in the US and the Netherlands with solutions that retrofit the gas turbines of LNG–fired power plants so they run on up to 65 percent hydrogen fuel. Following the 2021 project for the Linden Cogeneration Plant in New Jersey, in the US, we won the order in 2022 from Uniper, one of the world’s largest power producers, to retrofit their LNG gas turbines in Rotterdam, in the Netherlands. This transformational approach will help us move to a carbon neutral society. Recently, we teamed with Korea Western Power to develop technology that ramps up hydrogen content in gas turbines. We are working closely together to win the government’s demonstration project for F–class gas turbine hydrogen combustion.

We are intent on building long–term partnerships as we rapidly expand sales, customer service and R&D networks around the world. We’re strengthening our partnerships so we can provide better local customer service for our expanded product line. For example, we are working on securing vendor approvals from Saudi Aramco and other major clients in the Middle East and Asia. At the same time, our Houston R&D Center in the US is accelerating co–development efforts for innovative projects on a global scale. One of these joint development projects is to build a sCO2 Power Systems with the Southwest Research Institute (SwRI), an independent R&D nonprofit group based in Texas, in the US. Looking ahead, we plan to further strengthen the competitiveness of our existing businesses and expand into new areas, such as developing a product lineup for eco–friendly ships and successfully implementing the sCO2 projects. In addition, we will become a global leader in power and energy solutions by using future engineering technology that helps the green environment.

Hanwha

www.htpchem.com

- 2022 Total Sales

- 10,837 In USD millions

- 2022 Total Assets

- 5,942 In USD millions

EXPERTISE

- Ethylene, propylene, butadiene, EO, EG, SM, PX, PE, EVA, PP, gasoline, diesel, jet fuel, LPG, solvents

Hanwha TotalEnergies Petrochemical is a comprehensive material and energy company that produces high value–added multi-material and energy products. Since it was founded in 1988, we have led the growth of the petrochemical business in South Korea through technological innovations and by successfully executing a market expansion strategy. In 2003, we began building the foundation to become a global chemical and energy company. We executed that plan by forming a joint venture with the TotalEnergies Group, a major French company in the energy and chemical industry. Since then, we have continued to lead South Korea's petrochemical market and grow as South Korea’s leading company through product innovations, strategic diversified investments and economies of scale.

-

-

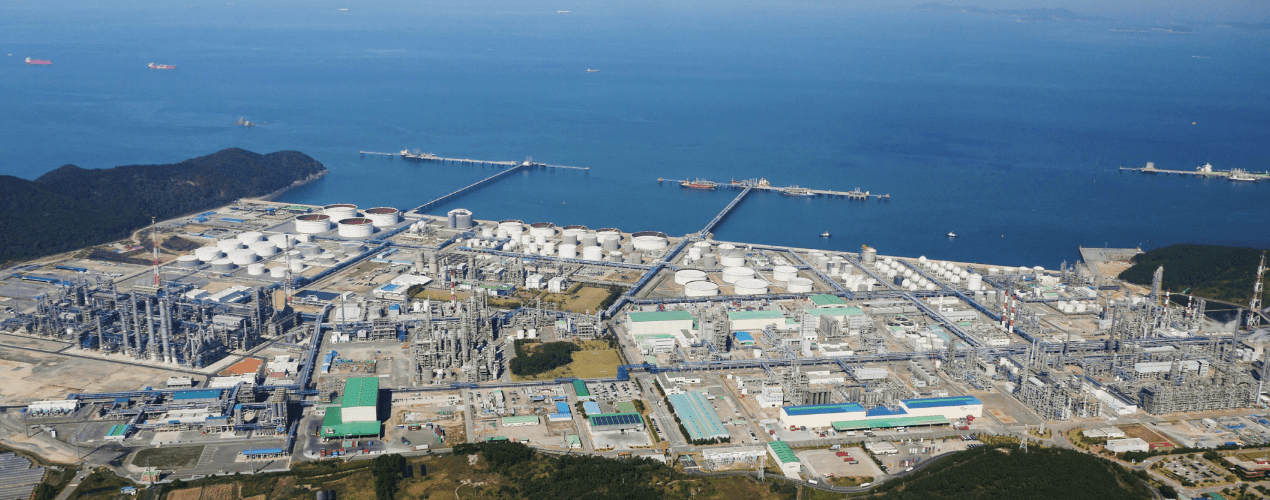

Our product portfolio includes monomers, such as ethylene, propylene and butadiene. We also produce base chemicals like styrene monomer, paraxylene and ethylene glycol. With 20 plant units in the Daesan Petrochemical Complex, we can produce a wide range of products needed for energy, from gasoline, diesel, jet fuel and liquefied petroleum gas to polymers such as polyethylene, propylene and EVA.

We are the first company in South Korea to operate a naphtha–cracking center (a core facility in our petrochemical plant), a condensate fractionation unit (a refining facility) and an aromatics plant, all in a single complex. This complex represents a successfully organized vertical integration system—from sourcing to producing to distributing final products. The efficiency we’ve achieved with this system allows us to diversify our business portfolio and pursue stable growth.

Annually, we now produce 1.53 million tons of ethylene, 2 million tons of paraxylene, 1.04 million tons of styrene monomer and 1.12 million tons of polypropylene. In 2020, as part of expanding our high value–added products, we built an additional plant for ultra–high molecular weight polyethylene used as a secondary battery separator, which secured an annual production capacity of 140,000 tons.

-

Daesan plant

Daesan plant

-

Our market dominance is built on a solid foundation. Globally, we hold the No. 1 market share in numerous markets, including solar grade EVA; HDPE used in bottle caps; EVA used in extrusion coating; flow mark free polypropylene (FMF PP) used in automotive composite materials; high isotactic polypropylene (HIPP) used in electronic applications; and protective polypropylene films for display products. These products have been recognized as World Class Products by South Korea’s Ministry of Trade, Industry and Energy.

To grow into a global leader in the material and energy industries, we plan to optimize operations by diversifying our raw materials while strengthening high value–added products and expanding markets. We will also strengthen high value-added products as we focus on expanding markets in the energy business. We expect to realize our vision by increasing sales of high value-added products and diversifying in the polymer business while boosting eco–friendly businesses by developing eco–friendly materials and technologies. Moving forward, in order to enhance our global competitiveness, we remain committed to leveraging synergies between our company and Hanwha Group's chemical and energy affiliates.

Hanwha Advanced Materials

www.hwam.co.kr- 2022 Total Sales

- 409 In USD millions

- 2022 Total Assets

- 473 In USD millions

EXPERTISE

- Automotive materials, solar materials

Founded in 1965, Hanwha Advanced Materials has developed an innovative line of environmentally conscious products and technologies that meet the needs of our customers around the world. We developed local production plants and R&D centers in South Korea, the US, Europe and China. In December 2022, we were spun off from Hanwha Solutions to enhance our business expertise and operational efficiency. With our lightweight composite materials and solar materials, we are recognized as a global advanced materials specialist.

-

-

Since entering the automotive materials business in 1986, we have launched a diverse portfolio of products for automobile structures and interiors. We now utilize original technologies to build high–strength, super–lightweight materials and parts. Our product line includes: StrongLite (Glass fiber Mat reinforced Thermoplastics), SuperLite (Lightweight Reinforced Thermoplastics), Expanded Polypropylene (EPP), Sheet Molding Compound (SMC), Long Fiber Reinforced Thermoplastics (LFT) and Continuous Fiber Reinforced Thermoplastics (CFRTPC). As the only company in the industry that produces multiple types of materials and molded products, we are well prepared to provide various components and solutions.

Being a global supplier, we have manufacturing factories in Alabama and Virginia in the US; in Beijing, Shanghai and Chongqing in China; in the Czech Republic in Europe; and in Mexico in North America. We are a major supplier to global automakers, including Hyundai, Kia, BMW, Daimler, Volkswagen, GM, Ford and Toyota. With superior technology and quality, our StrongLite and SuperLite materials claim to have the highest market shares worldwide in their respective categories.

To lead the changing industry as the automotive market emphasizes the lightweight trend, Hanwha Advanced Materials is continuously strengthening our R&D system. We are focused on researching thermoplastic and thermosetting composite materials, as well as designing and developing new applications. We are also developing new materials and manufacturing methods to offer improved functionality and innovative plastic hybrids that represent the latest technologies in the market. Currently, we are tracking the transition in the automotive market as smart cars and electric vehicles take larger roles. With specialized technology capable of designing various physical properties, such as high strength, ultralight weight and eco–friendliness, we are in strong position to expand into new businesses.

-

Lightweight composite materials for automotives

Lightweight composite materials for automotives

-

In solar materials, we have secured a stable market chain in the supply of raw materials sales with our vertical integration and Hanwha’s solar value chain. With production knowhow gained from three decades of experience, we have developed independent technology to produce EVA sheets and backsheets for modules as we expand our market into Europe, America and Southeast Asia. Being the only company capable of producing large–scale products using the Calender and T–Die method, we are demonstrating outstanding performance in the global market.

Hanwha Advanced Materials will expand businesses by growing in the North American market and becoming an inimitable global No. 1 company in the high–performance lightweight composite materials business.

- 2022 Total Sales

- 5,311 In USD millions

- 2022 Total Assets

- 2,640 In USD millions

EXPERTISE

- Petrochemical feedstock production

YEOCHUN NCC operates the world’s leading naphtha–cracking facility in the Yeosu National Industrial Complex. Built in 1999, the facility is located on the southern tip of the Korean Peninsula. We are a fifty–fifty joint venture of Hanwha and DL, the two South Korean conglomerates that own naphtha–cracking facilities. Supported by a steady flow of investments, product specializations, facility expansions and intense business focus, we are one of the top Naphtha Cracking Center (NCC) companies in the world.

-

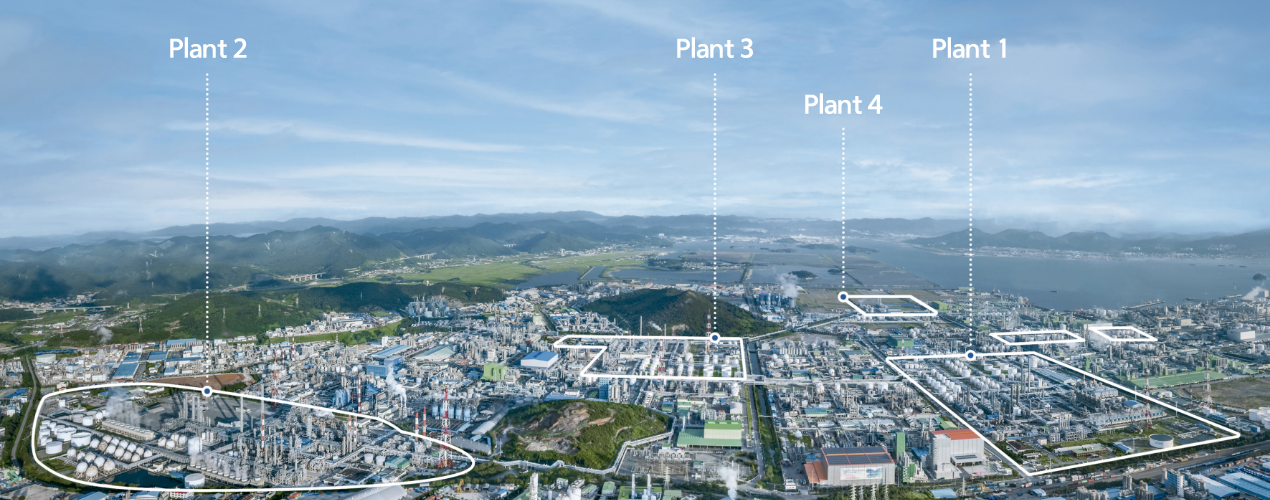

Aerial view of the plants

Aerial view of the plants

-

Our technologically advanced facility has large–scale production capacities that annually produce 2.29 million tons of ethylene, 1.29 million tons of propylene and 6.20 million tons of various base chemicals, including benzene, toluene, xylene, styrene monomer and butadiene. With fully automated and optimized processes producing high–purity feedstocks, this state–of–the–art facility gives Hanwha affiliates a competitive edge in producing high–quality downstream petrochemical products.

-

Plant 1

Plant 1

-

We attribute our improvements and growth each year to loyal customers, a sophisticated management system and a sound financial structure. Additionally, our professional and highly skilled employees effectively combine industry expertise with cutting–edge technology, truly making our workforce a key differentiator. We are extremely focused. As we continue to improve our capabilities, expansion will propel us around the globe.