Big Data Boosts Smart Plant Innovation- Hanwha Total Petrochemical

Hanwha Total Petrochemical is a global leader in the field of petrochemicals, engaged in the manufacture and sale in more than 130 countries worldwide. The company boasts No. 1 market share in EVAs for solar cells and HDPE bottle caps on the world market. To be at the forefront of the fourth industrial revolution, Hanwha Total Petrochemical is implementing a big-data-driven smart plant solution.

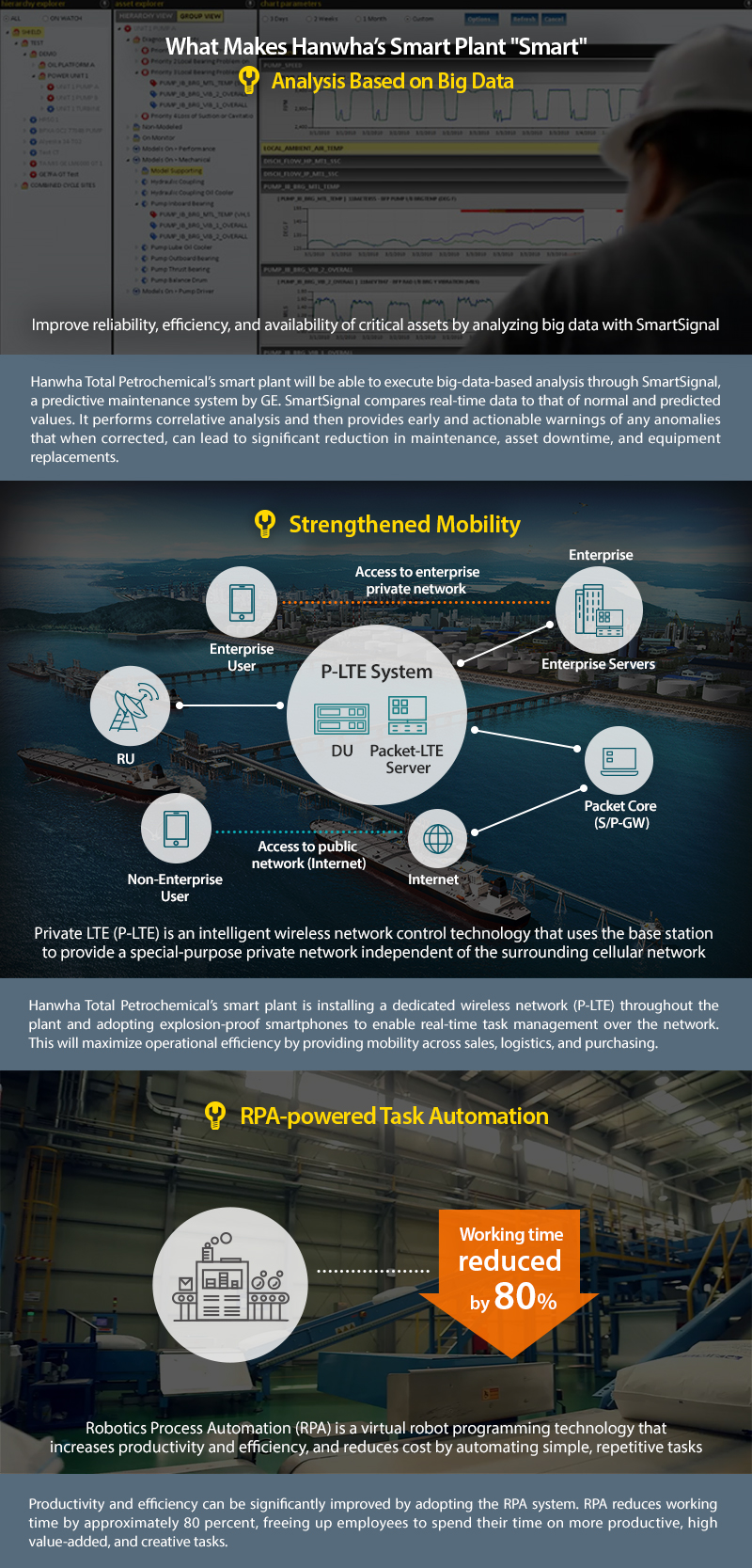

Hanwha Total Petrochemical's smart plant will be able to execute big-data-based analysis through SmartSignal, a predictive maintenance system by GE. SmartSignal compares real-time data to that of normal and predicted values. It performs correlative analysis and then provides early and actionable warnings of any anomalies that when corrected, can lead to significant reduction in maintenance, asset downtime, and equipment replacements.

Hanwha Total Petrochemical's smart plant is installing a dedicated wireless network (P-LTE) throughout the plant and adopting explosion-proof smartphones to enable real-time task management over the network. This will maximize operational efficiency by providing mobility across sales, logistics, and purchasing.

Productivity and efficiency can be significantly improved by adopting the RPA system. RPA reduces working time by approximately 80 percent, freeing up employees to spend their time on more productive, high value-added, and creative tasks.

Smart plants are expected to increase operational efficiency and allow for a quicker decision making by diagnosing the plant's status, detecting abnormal operations in advance, and managing the plant in real-time remotely. Hanwha Total Petrochemical's smart plant illustrates how through convergence with information technology, a traditional process industry can be transformed, harnessing the opportunities created by the fourth industrial revolution.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee