Developing Reliable Solutions with Eco-friendly Chemistry

The Hidden Dangers of Phthalate

Phthalates, mainly used as plasticizers, contain endocrine-disrupting chemicals that can change the hormone levels in people. Years of extensive studies reveal that they are toxic and extremely dangerous. So understandably, regulations on the use of phthalates worldwide are gradually being tightened, with production, sales and imports being banned across Europe since 2015.

Nevertheless, phthalates remain a vital component in many everyday products such as plastic bottles, cosmetics, toothpaste and hair sprays, making our exposure to them very difficult to avoid. However, Hanwha Total Petrochemical’s R&D is taking steps to eliminate our reliance on phthalates with new eco-friendly catalysts.

Protecting People with “Phthalate-free” with Eco-friendly Polypropylene Catalyst

Roughly 50 million tons of Polypropylene (PP) are produced worldwide each year in the form of food containers, medical equipment, household appliances, and automobiles. Between 80-90% of the PP production process employs Ziegler-Natta catalysts, where phthalates are used as internal donors, the core component of the performance controller. This means that approximately 80 to 90% of the products we use every day can contain trace amounts of phthalate and thus the need for phthalate-free products are commensurately high.

Understanding the gravity of the situation, since 2009, the catalyst research team at Hanwha Total Petrochemical has been cultivating the next generation of eco-friendly PP catalysts. And in 2015, they made a breakthrough, successfully developing environmentally friendly PP catalysts by replacing phthalate with eco-friendly chemical compounds as internal electron donors.

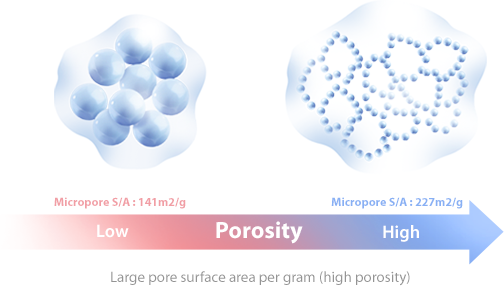

The next-generation eco-friendly PP catalyst created by Hanwha’s R&D team is completely phthalate-free and applies proprietary micropore carrier that boosts the activity and stereoregularity of the catalyst process. Moreover, PP products applied with the eco-friendly catalyst achieve the same levels of material property machinability as those that use standard catalysts and thus, make them versatile enough to be used in almost any product.

Total Petrochemical’s Eco-friendly PP Catalyst

Phthalate 0%

Phthalate 0% High activity

High activity High stereoregularity

High stereoregularity- ¹ Fraunhofer-Gesellschaft: A leading government-funded research organization is the largest in Europe in applied research with 69 institutes and research facilities in Germany along (7 in the US). The organization focuses on applied research to commercialize technologies developed by universities and institutes.

- ² Good Laboratory Practice (GLP): Regulation on systemic control of research personnel, laboratory facilities and equipment, and test methods to ensure the reliability of safety evaluations and toxicity tests of medicines and cosmetics

Protecting the Environment with Eco-friendly Technologies

Hanwha is discovering solutions for many problems besides the endocrine-disrupting chemical like the phthalate that can harm the human body. It is also taking the lead in developing eco-friendly technologies that are environmentally-safe. Hanwha has succeeded in developing eco-friendly plasticizers, halogen-free compounds and solid hydrogen storage materials.

The research teams operating under Hanwha’s petrochemical businesses are vigorously trying to solve environmental problems and developing eco-friendly technologies that can become the next generation of products for the petrochemical industry. In so doing, Hanwha stands at the forefront of petrochemical R&D and will continue to build on this position as an eco-friendly petrochemical industry leader.

Cases of successful development of eco-friendly technologies by

-

Eco-friendly Plasticizer

Hanwha Chemical has developed a non-phthalate-based eco-friendly plasticizer³ and is now preparing it for commercial production. However, the company’s R&D continues its research on functional plasticizers that do not harm the environment and to develop new processes, improve stability, and machinability.

- ³ Plasticizer: Organic substances added to plastics and paints in order to make processing of materials easier at high temperatures

Hanwha Chemical has developed a non-phthalate-based eco-friendly plasticizer³ and is now preparing it for commercial production. However, the company’s R&D continues its research on functional plasticizers that do not harm the environment and to develop new processes, improve stability, and machinability.

- ³ Plasticizer: Organic substances added to plastics and paints in order to make processing of materials easier at high temperatures

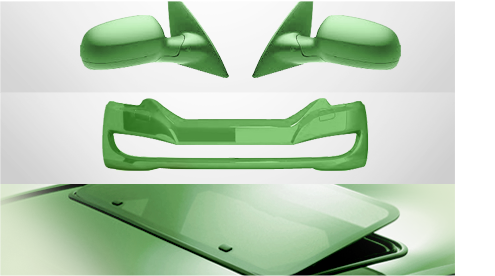

Demand for eco-friendly electronic, automobile and construction products that do not contain halogen is increasing in all areas of the compound market. Hanwha Chemical produces an environmentally friendly, nonflammable⁴compound which does not contain harmful substances like halogen? elements, RoHS?, toxic metals, phthalates or VOCs?. They do, however, offer superb material property and economic feasibility.

- ⁴ Nonflammable: Characteristics of resistance to fire even when exposed to flammable situation

- ? Halogen: A substance that is likely to cause human toxicity and endocrine problems due to elements such as fluorine, chlorine, and bromine.

- ? RoHS (Restriction of the use of Hazardous Substances): Restriction on the use of hazardous substances like Hg, Pb, Cd, Cr6+, PBB, PBDE.

- ? VOCs: Volatile Organic Compounds.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee