Rethinking Plastics & Sustainability

With concerns over global pollution mounting more than ever, people all over the world are looking into ways to reduce their impact on the environment. But lost within the discussion about the need to adopt more recyclable and alternative materials is an unexpected fact: plastic can actually have a net positive effect on the environment.

Plastic lowers environmental costs

Polypropylene (PP) is a lightweight, heat-resistant, and non-toxic plastic material that is used in everyday items from baby bottles to household appliances. When used in food packaging, PP and other types of plastic can help REDUCE FOOD WASTE BY UP TO 20 PERCENT by preventing millions of tons of food from spoiling and ending up in landfills.

Hanwha Total Petrochemical is one of the major producers of PP currently being used around the world.

Plastic packaging helps to preserve food, thereby reducing an enormous amount from going to waste (source: Getty Images Bank)

Using plastic can have a real financial impact, as well.

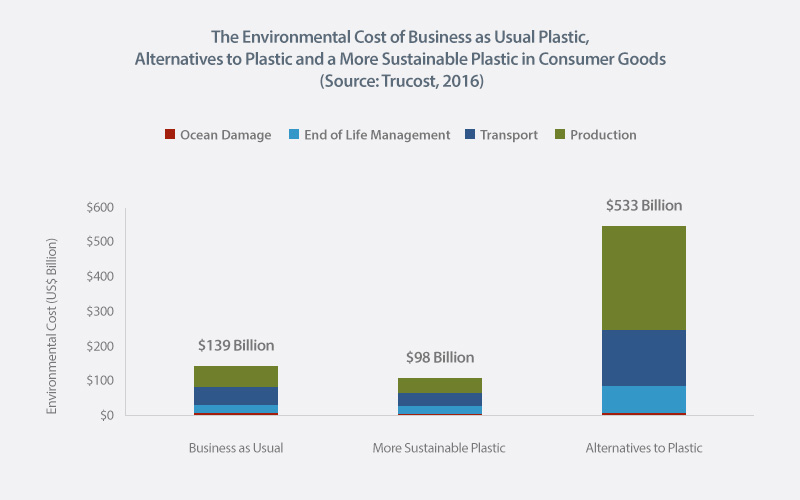

A series of studies by Trucost , a global environmental data and risk analysis company, showed that using alternative materials instead of plastic in consumer products and packaging actually increases environmental costs by nearly four times, from USD 139 billion to USD 533 billion, annually.

The negative impact on environment is greater when we substitute plastic with alternative materials

Plastic can drive sustainability

Plastic is now the material of choice in automobile manufacturing. Modern innovations mean today’s plastics can take up to 50 percent of a vehicle’s volume but account for only about 10 percent of its weight.

Advanced polymer materials, such as StrongLite glass mat reinforced thermoplastics (GMT) produced by Hanwha Advanced Materials, are as DURABLE AS STEEL, BUT IS 20 TO 25 PERCENT LIGHTER. They are commonly used to produce components such as bumpers, seatback frames, undercovers, and exterior covers for undercarriages.

Automobile manufacturers are increasing the amount of plastic they use to reduce weight and improve fuel economy

Lighter vehicles consume less fuel, emit less carbon and nitrogen oxide throughout their lifespans. For the average passenger car, a 10 percent reduction in weight translates into a FIVE TO SEVEN PERCENT REDUCTION IN FUEL CONSUMPTION.

What’s even more impressive is that the latest transcontinental airliners’ use of plastic composites have been so efficient that they can match the fuel economy of the average family vehicle on a per passenger basis.

Plastic in clean energy

Ethylene Vinyl Acetate (EVA) copolymers are used in a wide variety of applications because they are durable, UV resistant, and waterproof.

One example of EVA application is in solar power. Laminating films made from EVA copolymers are vital for the longevity of solar cells and modules. By protecting the cells and modules’ photovoltaic elements from rain, dust, shock, and UV rays, EVA films provide protection, allowing efficiency to be maintained and operate without issues in even the harshest environments for decades.

Hanwha Chemical is the world's largest producer of EVA, with 35 percent market share, the largest in the world. As a result, the EVA produced by Hanwha Chemical and Hanwha Total Petrochemical and used in the production of solar cell EVA, has been designated as a "World-class Product" by the Ministry of Trade, Industry and Energy of Korea. Hanwha Total Petrochemical’s market leadership can be traced back to its commitment to quality, innovation, and having successfully become the world’s first to commercialize its production of solar cell EVAs using tubular reactor polymerization.

Plastic hybrids are the ideal material to use for manufacturing clean energy products such as solar modules, which require durability and weather resistance

Getting the most out of plastic

Plastic can also be environmentally friendly because of the myriad ways it can be dramatically reduced for disposal or recycled.

New technologies, like cold plasma pyrolysis, allow for increasing amounts of usable material to be recovered during recycling. Gasification, meanwhile, can turn plastic into synthetic gasoline and diesel.

The latest developments in plastic manufacturing has led to the development of PP, a plastic product that can be reduced to very little waste because it can be produced without any additives and is 100 percent recyclable. Advancements in plastic recycling technologies has also allowed plastic materials to be recycled multiple times before it is finally discarded.

Plastic is still usable when it is at a point in its lifecycle called Energy from Waste (or Waste-to-Energy). This is when plastic can be burned to produce electricity, reducing the amount of plastic waste going into landfills.

Improvements in plastic recycling technology minimizes the environmental impact of plastic use

Hanwha committed to greener plastic

Hanwha is dedicated to reducing the environmental impact of plastic and going to great lengths to minimize its greenhouse gas emissions. Hanwha’s petrochemical plants process the byproducts of plastic manufacturing to create other products, recycle waste heat, and even use the steam generated during the production process to create electricity and reduce reliance on external power plants.

At Hanwha, we are dedicated to minimizing the environmental impact of plastic manufacturing

Plastic is an indispensable material today and will remain vital for the foreseeable future. Hanwha will continue to develop ways to ensure that plastic has a net positive environmental impact.

As a participant and advocate for the United Nations’ Sustainable Development Goals program, Hanwha is committed to finding solutions to address major challenges in the environment. From programs to reduce carbon emissions and industry waste to developing more eco-friendly materials and highly efficient renewable energy sources, Hanwha is helping businesses and society work towards a more sustainable future.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee