The ABCs of EBA: The Role of Ethylene Butyl Acrylate in the Energy Transition

In an era of striving for carbon neutrality, the spotlight is on energy-efficient cables.

Electrification, the process of replacing carbon-emitting technologies with electric alternatives, has been identified as one of the most crucial strategies for reducing emissions. Fueled in part by the growth of renewable energy infrastructure, such as solar and wind power, the planet’s electricity consumption continues to increase worldwide.

Alongside the rise of green energy technology, there is also a surging demand for high-voltage power cables used in energy transmission and distribution. Semiconductive materials, such as ethylene butyl acrylate (EBA), are key to manufacturing these power cables. As a result, the production of these materials is becoming an important factor in the global green energy transition.

In response to this rising demand, companies like Hanwha Solutions are localizing production and increasing the global supply of critical materials like EBA. Keep reading to understand the basics of power cables, the role of EBA in making them work, and how Hanwha is helping power progress for the energy transition.

The Highs and Lows of Power Cables

Before we charge ahead into why EBA is important to the energy transition, we first need to understand how we receive the electricity that powers our daily lives. Did you know that there are different levels of electricity? Voltage is like the "pressure" that pushes the flow of electricity, and higher voltages result in a higher flow of electricity. Different types of voltage serve specific purposes. For example, high voltage (HV) is used for power generation, transmission, and distribution, while low voltage (LV) powers smaller devices like electronics and appliances. Different voltages require different types of cables to transmit energy safely and efficiently.

The primary reason we use high-voltage transmission lines for power generation, transmission, and distribution is efficiency. As electricity is transmitted over long distances, there are inherent energy losses along the way. High-voltage transmission minimizes the amount of power lost as electricity flows from one location to the next. This is especially useful for renewable energy sources like solar and wind power, which are often located in remote areas. The green energy transition is sparking growth in renewable infrastructure and driving electrification — and in turn, the demand for high-voltage cables and their key components is also increasing. So, how does EBA lay the groundwork for these cables?

EBA Explained

Ethylene butyl acrylate (EBA) is a flexible semiconductive material created by combining ethylene and butyl acrylate molecules. A semiconductive material, or “semiconductor,” gets its name from its specific electrical properties: conducting electricity more than an insulator, such as glass, but less than a pure conductor, such as copper. Most of us are familiar with the semiconductor chips that power our electronic devices, such as computers, smartphones, and even cars. But in fact, semiconductive materials are also a key part of powering those same devices thanks to their critical role in power cables.

Hanwha’s EBA material

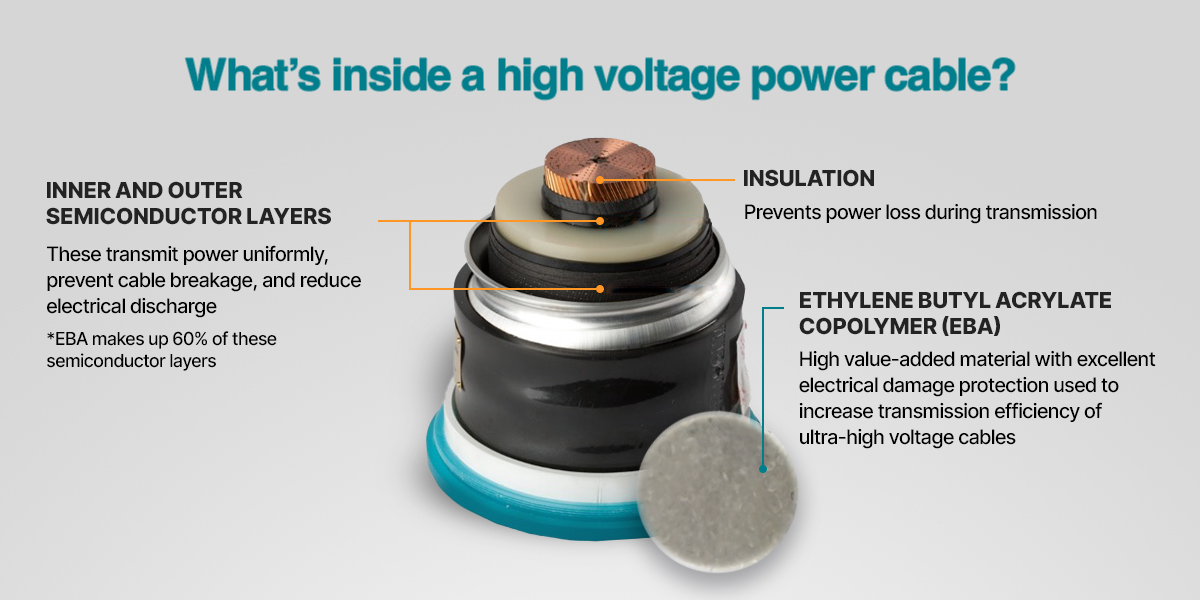

All power cables consist of layers, including a conductor, an insulating layer, and a semiconductive layer. High-voltage cables, however, have additional layers to control the electric field around the conductor. Without these layers, the cable would fail within minutes due to electrical stress. Within a power cable, the semiconductive layer helps ensure smooth and uniform power flow, prevent cable breaks, and minimize electrical losses.

While there are different types of semiconductive materials, EBA in particular shines with a range of useful traits: it is compatible with various materials, can withstand high heat, moisture, and damage, and is especially effective for insulating high-voltage direct-current power cables. Due to its reliable and versatile properties, EBA makes up at least 60 percent of the semiconductor layer in high-voltage power cables.

Thanks to this ability to effectively insulate high-voltage power cables, semiconductive materials like EBA are experiencing an increase in demand worldwide. As the world shifts towards cleaner energy sources and infrastructure, high-voltage cables play a vital role in maximizing the efficiency, capacity, and stability of energy transmissions. Now more than ever, global entities are tuned into the availability of these high-voltage cables, which are essential to delivering renewable energy where it is needed most.

Local Production, Global Impact

The numbers paint a clear picture: in order to achieve a global net-zero target by 2050, we need to more than triple clean energy investments to $4 trillion by 2030. This includes investments in crucial infrastructure, such as high-voltage cables. As a result, demand is also growing for EBA as a material that can bolster renewable energy infrastructure and improve energy accessibility.

High-voltage cables use EBA as the semiconducting layer

In fact, more than 50,000 tons of EBA are used globally each year. EBA finds its application in various power cables, from submarine cables that connect offshore wind power plants to land substations, to cables utilized in energy transmission and distribution at large power plants. Alongside other effective semiconductor materials, EBA will play a significant role in promoting a greener energy transition.

In 2022, Hanwha became the first Korean company to develop EBA, and the company plans to package it with cross-linked polyethylene (XLPE), another key material in MV and HV cable insulation. Hanwha’s EBA production will bolster availability to countries around the world, especially for exports to major overseas markets like China and the Middle East.

EBA is helping shape the future of power cables, improving efficiency and sustainability to advance the energy transition towards a cleaner future. As the world transforms its energy systems, Hanwha is ready to meet the rising demand for new power infrastructure and illuminate the path to a sustainable future.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee