The role of ESS and hydrogen fuel cells in maritime energy security

Most people rarely consider how the world’s goods or energy reach them. Smartphones made from globally sourced materials arrive within a day or two. Gas flows to stovetops, lights flick on, and fuel appears at the pump — all without a second thought. But behind this convenience lies a vast and often invisible system of global logistics and energy transport. At its core is the global shipping industry.

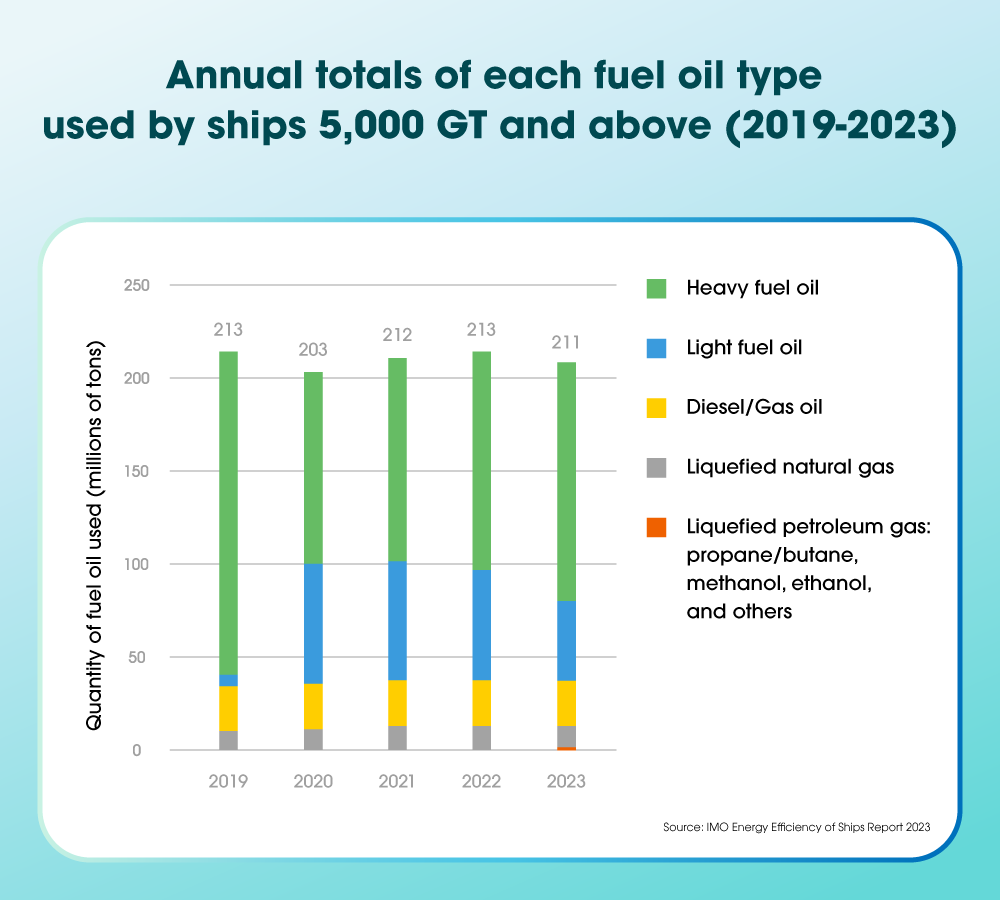

Around 80% to 90% of global trade moves by sea, including a significant share of the world’s fuel supply: 64% of oil, 17% of natural gas, and 15% of coal. Yet most vessels transporting this cargo still run on conventional oil-based fuels such as marine diesel or heavy fuel oil (HFO). This reliance creates a feedback loop: fossil fuels power the ships that deliver more fossil fuels — leaving global energy security exposed to fuel price shocks, geopolitical risk, and emissions regulations.

To build a more resilient maritime energy system, the shipping industry must evolve. That evolution begins with rethinking how ships are powered — not only to cut emissions, but to improve efficiency, reduce costs, and enhance long-term stability.

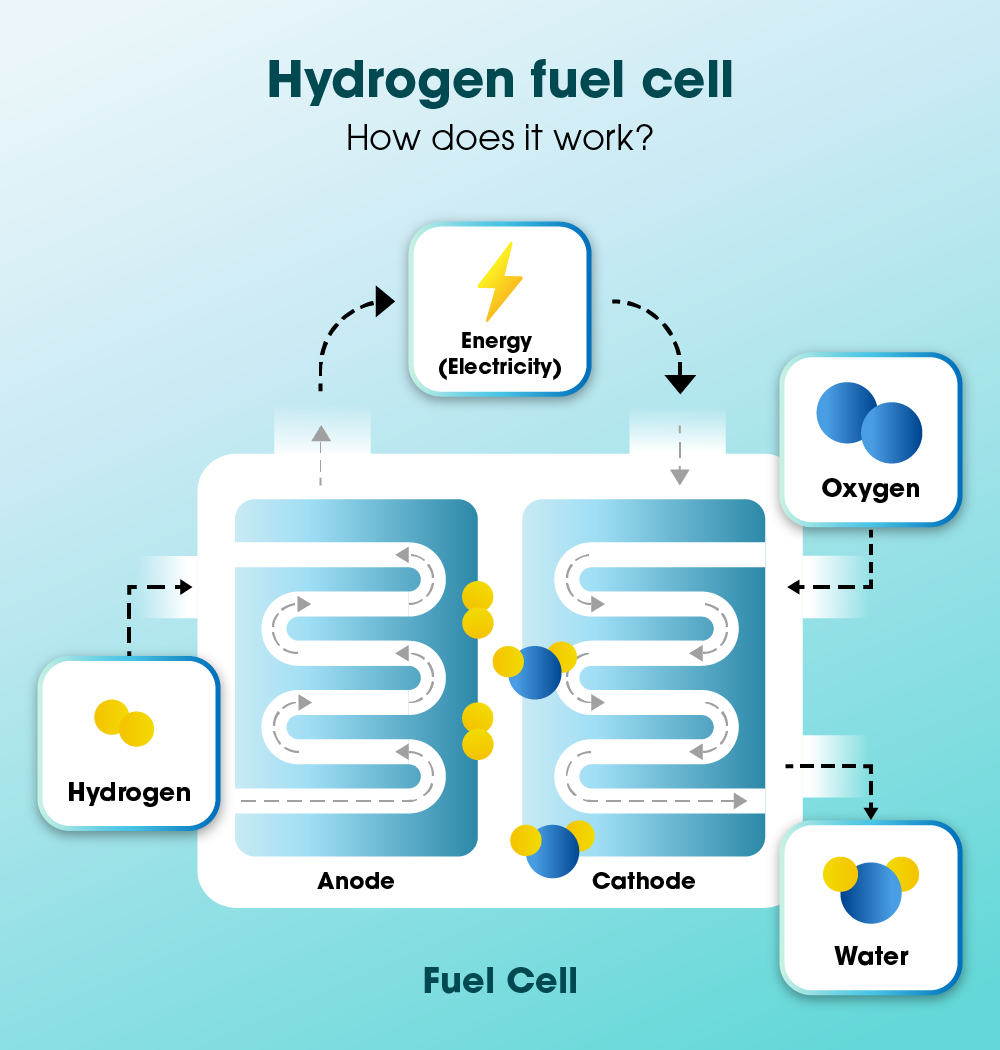

Electrification, through energy storage systems (ESS) and hydrogen fuel cells, offers a strategic path forward. ESS store electricity in onboard batteries for propulsion or auxiliary power, while hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, producing only water as a byproduct.

The benefits of electrifying shipping

Electrified vessels reduce dependence on fossil fuels, helping operators manage fuel price volatility and strengthen long-term energy security.

Electrification also offers a cleaner, quieter, and more cost-effective way to operate ships. Electric propulsion systems replace or supplement conventional engines with electric motors powered by ESS or hydrogen fuel cells. High-efficiency drivetrains convert energy directly into motion, minimizing energy losses common in traditional mechanical systems.

With fewer moving parts, electric systems experience less mechanical wear and require less maintenance — reducing lifetime operating costs. They also generate lower onboard noise and zero local emissions, making them well suited for populated ports and environmentally sensitive waters.

These benefits are already being realized. Ferries, tugs, and port service vessels, where routes are short and schedules predictable, are increasingly powered by batteries or hybrid systems. These ships cut fuel use during docking, idling, and low-speed operations, helping operators meet emissions regulations while reducing costs.

Electrification is no longer a future concept — it’s already in use, and its role will only grow as the technology continues to advance.

How we get there: The path to zero-emission vessels

Fully electric, ocean-crossing ships remain a long-term goal, as current technologies can’t yet power large vessels over extended distances. However, the foundation is being laid. The transition will be gradual, driven by advances in ship systems and infrastructure. Key technologies include ESS and hydrogen fuel cells, alongside other emerging propulsion innovations such as ammonia gas turbines.

ESS, already used in electric vehicles and power grids, are increasingly being integrated into maritime transport. On ships, they help manage load fluctuations, improve port maneuvering efficiency, and reduce fuel use. To support long-distance shipping, batteries must achieve higher energy density, lower weight, and greater onboard capacity.

Hydrogen fuel cells, widely used in land transport, are now being piloted at sea — initially to power auxiliary functions like lighting and onboard electronics. However, they are also being developed for main propulsion, offering a scalable, zero-emission solution. Despite their promise, challenges remain: hydrogen is difficult to store onboard in large volumes, and bunkering infrastructure is limited.

Ammonia, which stores hydrogen more easily and can be cracked onboard to supply fuel cells, offers a promising workaround.

Future fully electric ships will likely combine these technologies, enabling long-range, zero-emission operation — independent of global fossil fuel supply chains.

Hanwha: At the helm of innovation

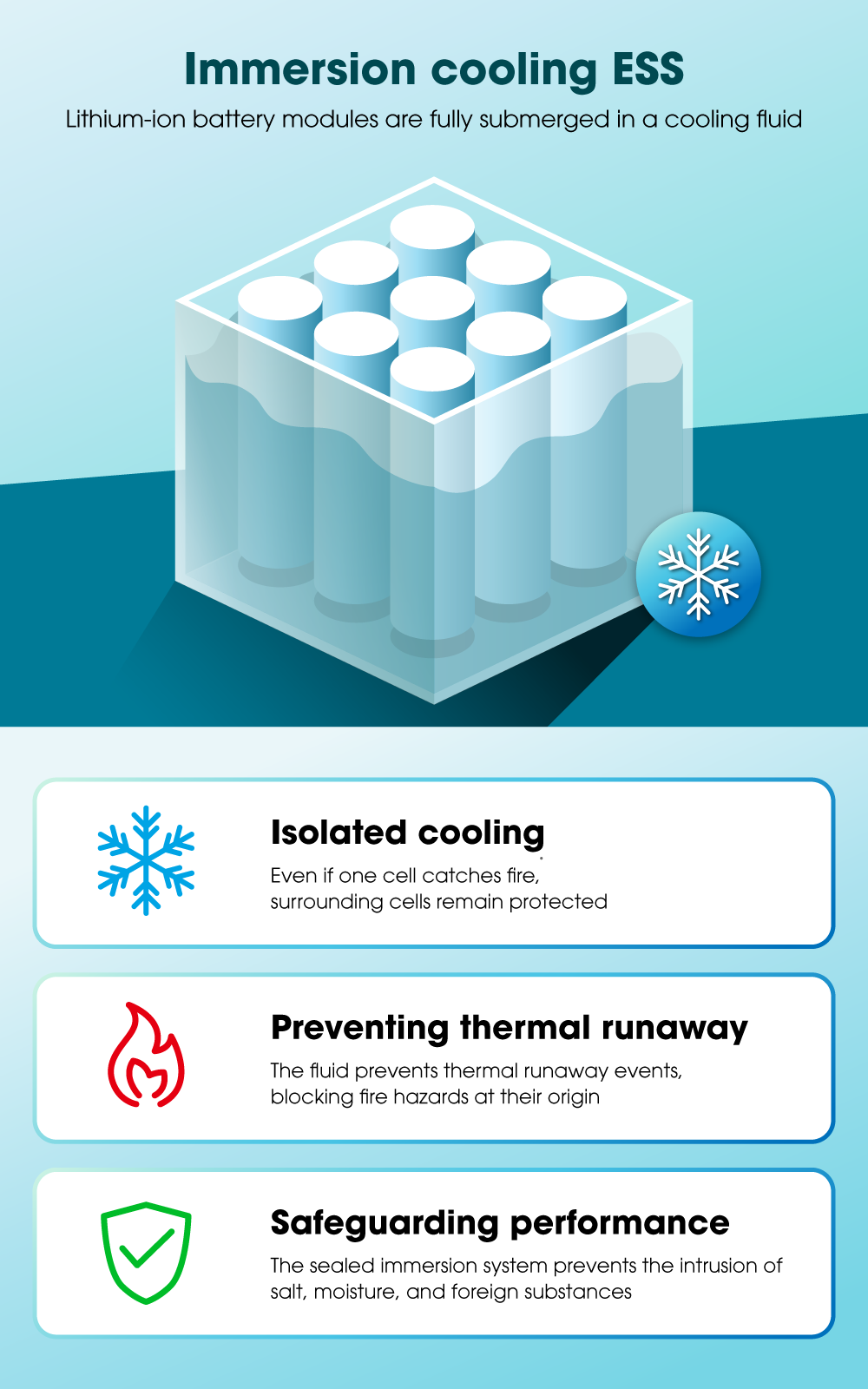

Hanwha is investing across the maritime value chain to accelerate the transition to cleaner, more resilient propulsion systems. Hanwha Aerospace is developing advanced ESS for both commercial and defense vessels — including lithium-ion battery storage systems designed to operate alongside air-independent propulsion in next-generation submarines. It has also introduced the world’s first immersion cooling ESS. Certified by both DNV and the Korean Register of Shipping, the system enhances fire safety by submerging battery cells in a non-flammable cooling fluid — preventing thermal runaway and improving reliability in harsh marine environments. This innovation marks a key step toward safer, more scalable electrification for commercial vessels.

In addition, Hanwha Aerospace has received Approval in Principle (AiP) from DNV for its 200kW hydrogen fuel cell system — a regulatory milestone that validates its safety, performance, and compliance with international standards. Combined with earlier approval from the Korean Register of Shipping, the certification positions the company to begin global commercialization of its maritime fuel cell technology.

Hanwha’s competitive strength lies in its ability to integrate across domains. Its companies work in coordination across energy generation, propulsion innovation, and vessel construction — enabling cohesive, future-ready platforms. This internal synergy reduces development timelines and minimizes supply chain risks.

With ongoing investments in ESS, hydrogen fuel cells, and integrated shipbuilding technologies, Hanwha is helping chart a more secure and resilient course for the global maritime sector.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee