Scaling circularity: How Hanwha’s

hydrogen gas turbine technology can transform industries

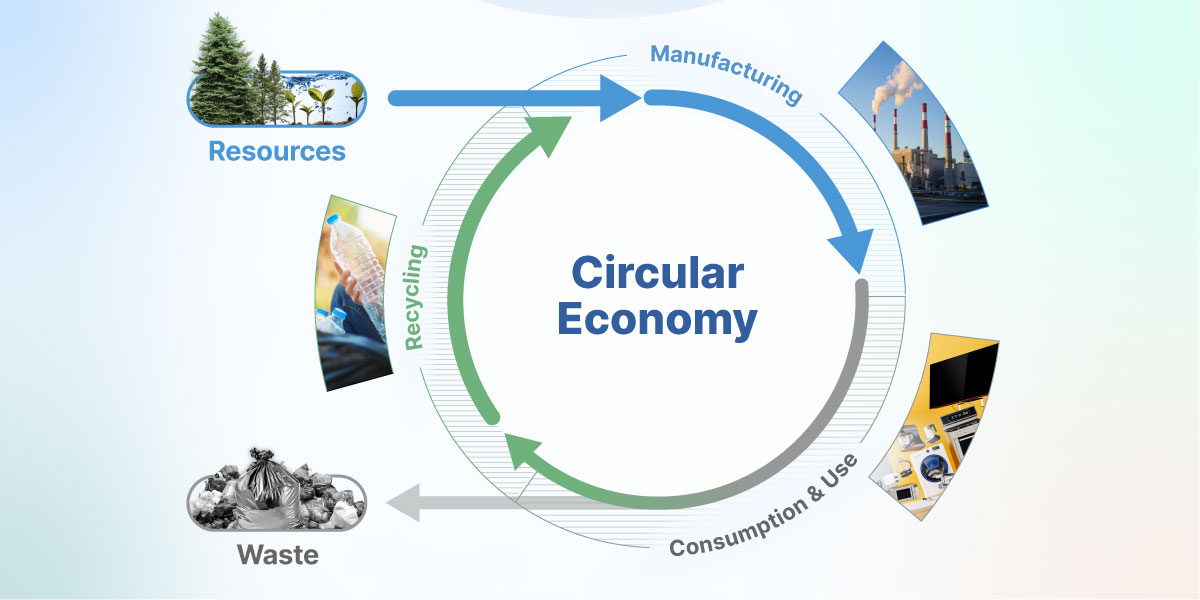

“Out with the old, in with the new.” Today’s world operates on a take-make-waste system that focuses on producing and selling as many products as possible — but that often comes at the expense of our planet's health.

Annually, the world consumes over 100 billion tons of raw materials and discards roughly 90 billion tons as waste. What are some unintended byproducts of this economy? Up to two-thirds of global GHG emissions, 90% of biodiversity loss, and two-thirds of air quality-related deaths.

Change is needed to put the world back on track to achieve net zero emissions by 2050, and one key tactic is circularity. Circularity means more than simply recycling; it embodies a shift in mindset —fostering waste prevention, minimizing resource extraction by reusing materials, and curbing environmentally harmful practices like mining and manufacturing for new infrastructure.

But circularity doesn’t just happen, and we can’t revolutionize our current systems overnight. Industry leaders need to rethink how things are done, which is why the World Economic Forum created the Circular Transformation of Industries. This cross-industry, multi-stakeholder initiative aims to enable a growing, resilient, and sustainable economy by adopting circularity at scale. As part of this initiative, Hanwha is scaling circularity, helping prevent stranded assets, and taking steps toward systemic change by utilizing one of its most cutting-edge innovations: Hydrogen gas turbine technology.

Read on to learn how Hanwha's recent project — included in a WEF white paper as an example of circularity in action — exemplifies sustainability, flexibility, and prosperity.

Paving the path to decarbonization

Hydrogen gas turbine technology offers a bridge between current profitability and green innovation by using hydrogen to power existing natural gas turbines. A study from 2022 found that in order to align with the Paris Agreement's 1.5°C target, a substantial portion — 60% of oil and gas reserves and 90% of known coal reserves — must remain untouched. This would render many fossil fuel resources unusable in the energy sector, leading to infrastructure like pipelines and power plants becoming useless before their expected lifespan. Termed as “stranded assets,” these unproductive holdings pose a major challenge to achieving the goals outlined in the Paris Agreement. In the oil and gas sector, these unprofitable or outdated assets are estimated to be worth over $1 trillion.

One way to prevent fossil fuel infrastructure from becoming stranded assets in the energy transition is by revamping them to run on alternative fuels, like hydrogen. Because hydrogen has no carbon and, therefore, produces no CO2 when burned, blending hydrogen and natural gas fuel produces less CO2 emissions than natural gas burned alone. Retrofitting natural gas turbines to run on hydrogen can, therefore, both reduce CO2 emissions and prevent stranded assets. Hanwha is putting this industry transformation into practice with a partnership that embodies both sustainability and innovation.

Fueling innovation with hydrogen gas turbine technology

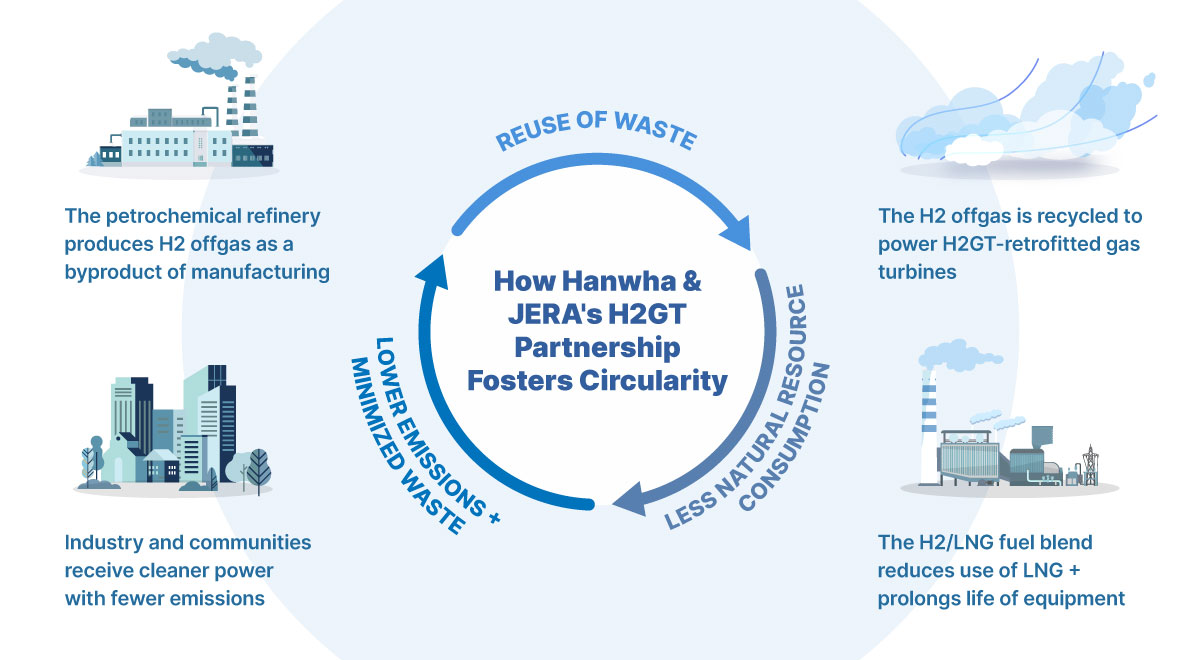

Hanwha's commitment to circularity shines through its hydrogen gas turbine retrofitting project at the JERA Americas-operated Linden natural gas power plant in New Jersey, USA. In this case, JERA Americas (JERA) and PSM, a Hanwha company, partnered to retrofit a gas turbine to burn hydrogen-containing refinery off-gas (RoG) produced by a nearby refinery operated by Phillips 66, transforming the “waste” hydrogen into a valuable fuel source. The retrofit included installation of Hanwha’s FlameSheet™ combustion system, the RoG/natural gas fuel blending and delivery hardware systems, gas turbine controller upgrades, and successful operational commissioning.

The retrofit improved both emissions and fuel efficiency for the gas turbine. Hanwha’s innovative FlameSheet™ technology significantly lowers the risk of flashback on gas turbines, which occurs when there is an imbalance between flame speed and fuel flow velocity. This disparity sends the flame back toward the combustion chamber, causing damage to the hardware and destabilizing the output. In addition, FlameSheet™ technology helps stabilize power generation, which reduces NOx emissions to single-digit values. The low levels of GHG emissions eliminate the need to replace the Selective Catalytic Reduction (SCR) system every time government air quality standards are updated, allowing conventional energy sources to evolve alongside the global green energy transition. In addition, using hydrogen as a fuel source also reduces the cost spent, in this case lowering the amount of natural gas purchased from JERA’s fuel supplier.

Revamping existing power assets instead of scrapping and replacing them also prevents waste and reduces the need to extract untapped resources. Gas turbines are made almost entirely of carbon, stainless steel, and nickel-based superalloys weighing about 225 tons or 450,000 pounds. By upgrading its equipment rather than purchasing new parts, JERA was able to reduce the environmental impact that would have resulted from mining and manufacturing. Notably, hydrogen fuel blends have been demonstrated to extend the lifespan of aging LNG-fired gas turbine parts by more than 20 years.

The retrofitting approach to fossil fuel infrastructure prioritizes refurbishment, repairability, and component recycling, all of which are key elements of a circular economy. By offering a cost-effective, reliable, dispatchable, and decarbonized solution to accelerate the energy transition, Hanwha is playing a pivotal role in transforming gas turbines to one day run on 100% clean hydrogen.

Embracing circular transformation

By using circularity as the guiding principle, Hanwha and JERA’s partnership was able to create a virtuous cycle. As a real-world example of the WEF’s Circular Transformation of Industries, Hanwha exemplifies how embracing circularity fosters sustainability, resilience, and prosperity in the evolving energy landscape.

Driven by the goal of “circularity with a purpose,” Hanwha aims to provide tangible solutions that promote circularity and set the stage for more measurable progress. At its core, responsible resource utilization and circularity aren't just buzzwords — they are practical strategies that further sustainability and safeguard against the creation of stranded assets.