At Gastech 2025, Hanwha presents a suite of cradle-to-retrofit vessel lifecycle solutions

As global regulations tighten and alternative fuel pathways emerge, the maritime sector is under increasing pressure to modernize. The International Maritime Organization (IMO) has set the goal of cutting shipping emissions by at least 50% by 2050, with more ambitious goals under consideration. Meeting these targets requires building new, future-ready vessels while upgrading the existing fleet with minimal disruption.

However, fleet renewal is costly and time-intensive. Newbuild lead times often take years depending on vessel class and shipyard capacity. Meanwhile, global LNG demand continues to rise, with maritime transport accounting for a substantial share of energy logistics and over 80% of global trade by volume. Faced with these pressures, shipowners are now turning to incremental upgrades and mid-life vessel retrofits, provided by companies like Hanwha, to keep fleets commercially viable.

Hanwha’s cradle-to-retrofit approach at Gastech 2025

Under the theme “powering a sustainable energy future,” Gastech 2025 convened more than 50,000 policymakers, executives, and engineers in Milan. There, attendees explored many of the technologies and strategies shaping the future of global energy. Alongside topics like carbon capture systems (CCS), hydrogen, and AI, Gastech highlighted the role of the maritime sector in energy security — both as a cornerstone of global fuel transportation, and as a catalyst for alternative fuel adoption.

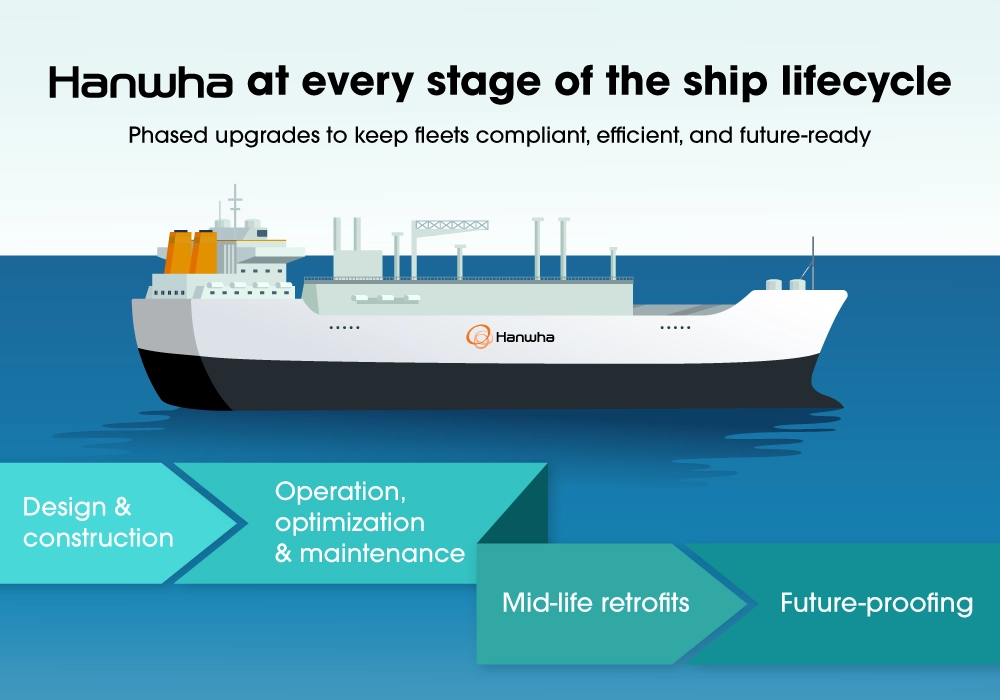

At this year’s event, Hanwha presented its cradle-to-retrofit strategy, a set of end-to-end lifecycle solutions that span maritime vessel design, operations, retrofits, and propulsion technologies.

Emphasizing compliance, efficiency, and resilience, Hanwha’s approach helps extend the lifespan of existing fleets while giving shipowners practical, phased options to adapt to new regulations and fuel pathways.

1. Design & construction

New vessels face rising regulatory and market pressures from the outset. Hanwha’s design approach embeds flexibility early through modular layouts and integrated emissions management.

- Smart yards optimize construction timelines and quality control through digitalized workflows.

- Vessels are built with systems and space ready for future upgrades — such as dual-fuel engines or carbon capture units — reducing future retrofit costs and downtime.

- The delivery of Hanwha’s 200th LNG carrier in 2025 highlights its ability to deliver fuel-flexible, regulation-ready vessels at scale.

2. Operation, optimization, and maintenance

As fuel costs rise and compliance standards tighten, operators need tools that sustain vessel performance over decades of service.

- The HS4 smart ship supports real-time monitoring, predictive maintenance, and optimized routing to reduce fuel use, lower emissions, and prevent costly downtime.

- Integrated systems — including integrated automation systems (IAS), alarm monitoring systems (AMS), and integrated control and monitoring systems (ICMS) — unify navigation, diagnostics, and emissions data to improve decision-making and streamline compliance.

- Lifecycle-based maintenance, repair, and operation (MRO) services keep vessels safe and updated throughout their lifespan. Hanwha operates at Geoje Shipyard and the soon-to-be-transformed Hanwha Philly Shipyard, expanding global repair and retrofit capacity. To date, Hanwha has completed MRO for a number of vessels.

3. Mid-life retrofits

With fleet renewal lagging behind policy shifts, shipowners need proven, modular retrofit solutions to keep vessels compliant and commercially viable.

- Engine and fuel system adaptations, including dual-fuel conversions for LNG, methanol, or ammonia.

- Energy-saving upgrades such as rotor sails and air lubrication systems to reduce fuel use and emissions.

- Onboard carbon capture systems (OCCS) for high-emission routes and harder-to-abate segments.

- Boil-off gas (BOG) re-liquefaction systems to improve energy use and cargo profitability.

- Propeller and hull optimization to increase efficiency without major structural changes.

4. Futureproofing

To meet long-term net-zero targets, vessels will need propulsion systems that move beyond traditional fuels altogether. Hanwha is investing in next-generation technologies that will power the fleets of tomorrow:

- With Approval in Principle (AiP) from the American Bureau of Shipping (ABS) secured at Gastech 2025, Hanwha’s ammonia gas turbines will eliminate the need for pilot fuel, enabling zero-emission propulsion.

- A research agreement with ABS, also signed at the event, will advance U.S. maritime cybersecurity standards and help to shape global regulations.

- Hanwha’s SecuAider platform further strengthens cybersecurity at sea, protecting increasingly connected fleets from digital threats and disruptions.

- Immersion-cooled energy storage systems (ESS) provide safer and more compact energy storage for hybrid and electric vessels — certified by DNV and the Korean Register.

- Hydrogen fuel cells, for which Hanwha holds AiP from DNV, offer another clean power pathway and enhance fuel diversification.

These future-facing technologies will support the emergence of fully zero-emission vessels, while giving shipowners strategic flexibility as global regulations continue to evolve.

A total marine lifecycle partner

Together, these solutions form a phased roadmap for shipowners navigating uncertainty. Smart design builds flexibility into new vessels, operations and MRO sustain performance over decades, vessel retrofits deliver near-term pathways for compliance and efficiency, and propulsion technologies prepare fleets for long-term transitions. This layered approach provides energy companies with greater confidence that vessels carrying LNG and emerging fuels will remain compliant and commercially operational — strengthening global supply chain resilience. By combining shipbuilding, propulsion, energy systems, and digital expertise, Hanwha is positioning itself as a total marine lifecycle partner that provides a practical pathway to the next generation of shipping.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee