What is GMT and how does it reduce the weight of electric vehicles?

In 2007, the first smartphone transformed how people live and work, but few could have predicted that it would become an indispensable tool for people all over the world. A similar shift is now underway in the automotive industry. Once a niche alternative, electric cars have surged to account for over 20% of global car sales — a sharp increase from just 4.4% in 2020.

However, rapid adoption comes with engineering tradeoffs. Despite advances in energy density and electric vehicle (EV) efficiency, batteries remain heavy, with many large packs weighing about 500 kilograms. That added weight increases the overall weight of the car, reducing range, affecting handling, and accelerating wear on components such as tires, brakes, and suspension systems.

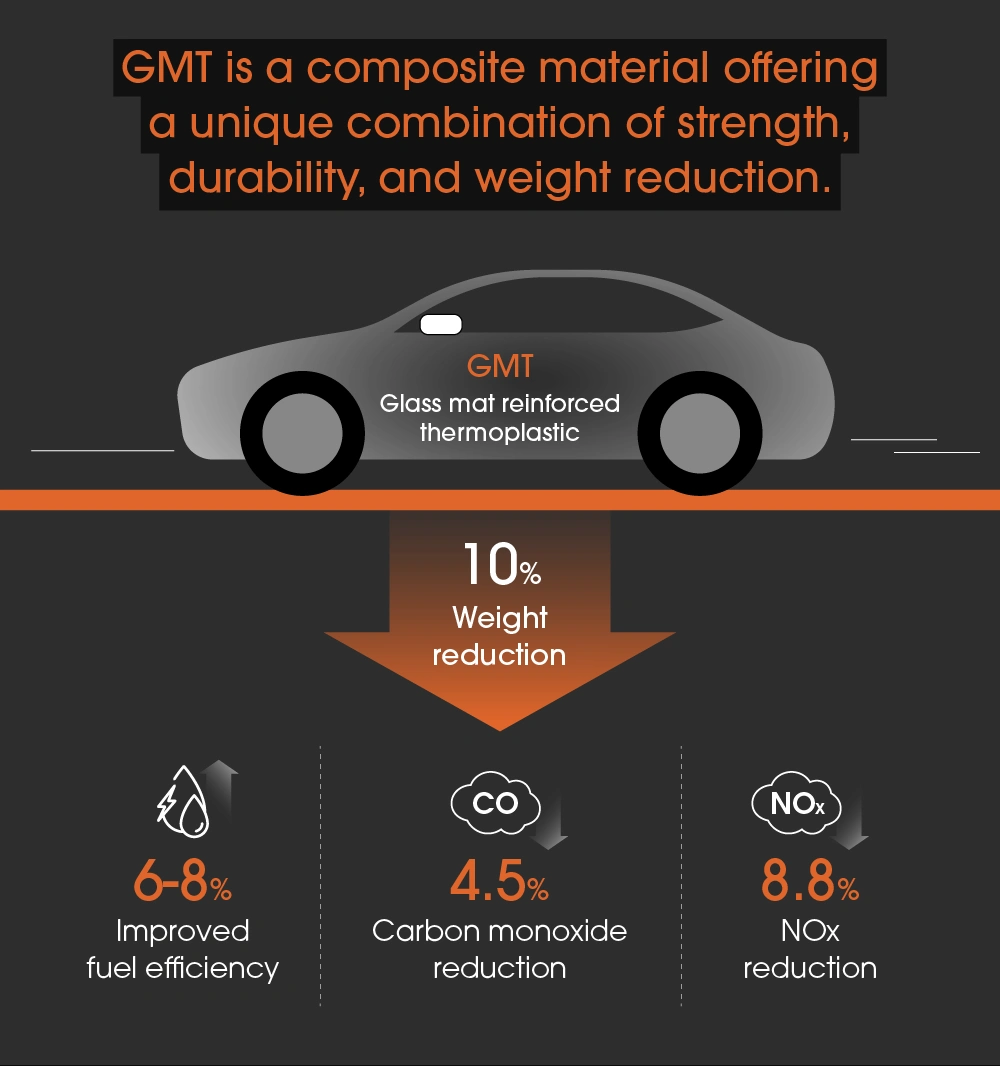

To compensate, automakers are rethinking how vehicles are built, including the materials themselves. One innovation that is quietly vital to lightening the load is glass fiber mat reinforced thermoplastics (GMT), a high-performance composite material that offers a unique combination of strength, durability, and weight reduction. Already used in components such as car bumpers, underbody shields, and seat back frames, GMT is helping redefine how lighter, safer electric vehicles are made. Here are five facts about GMT — the material quietly reshaping the future of EV design.

1. GMT helps reduce EV weight without sacrificing strength

GMT is made by layering fiberglass mat between sheets of thermoplastic resin — most often polypropylene. This pairing provides reinforcement from the glass and flexibility from the plastic, resulting in a material that is both strong and formable.

Structurally, GMT consists of a five-layer design: three layers of polypropylene resin and two layers of glass fiber mat, delivering a balance of strength and moldability.

With a high strength-to-weight ratio, GMT delivers steel-like performance at 20% to 25% less weight. In some cases, component weight can be reduced by 40% to 50%. This matters because in conventional vehicles, a 10% reduction in weight can improve fuel economy by 6% to 8%. In electric vehicles, lightweight materials help offset the added mass of EV batteries and motors — improving range, supporting efficiency, and potentially reducing the required size of the battery pack.

As demand for lightweight solutions grows, the global GMT market is projected to increase from $760 million in 2024 to $890 million by 2032 — supported by an estimated 19% compound annual growth rate in battery electric vehicle production.

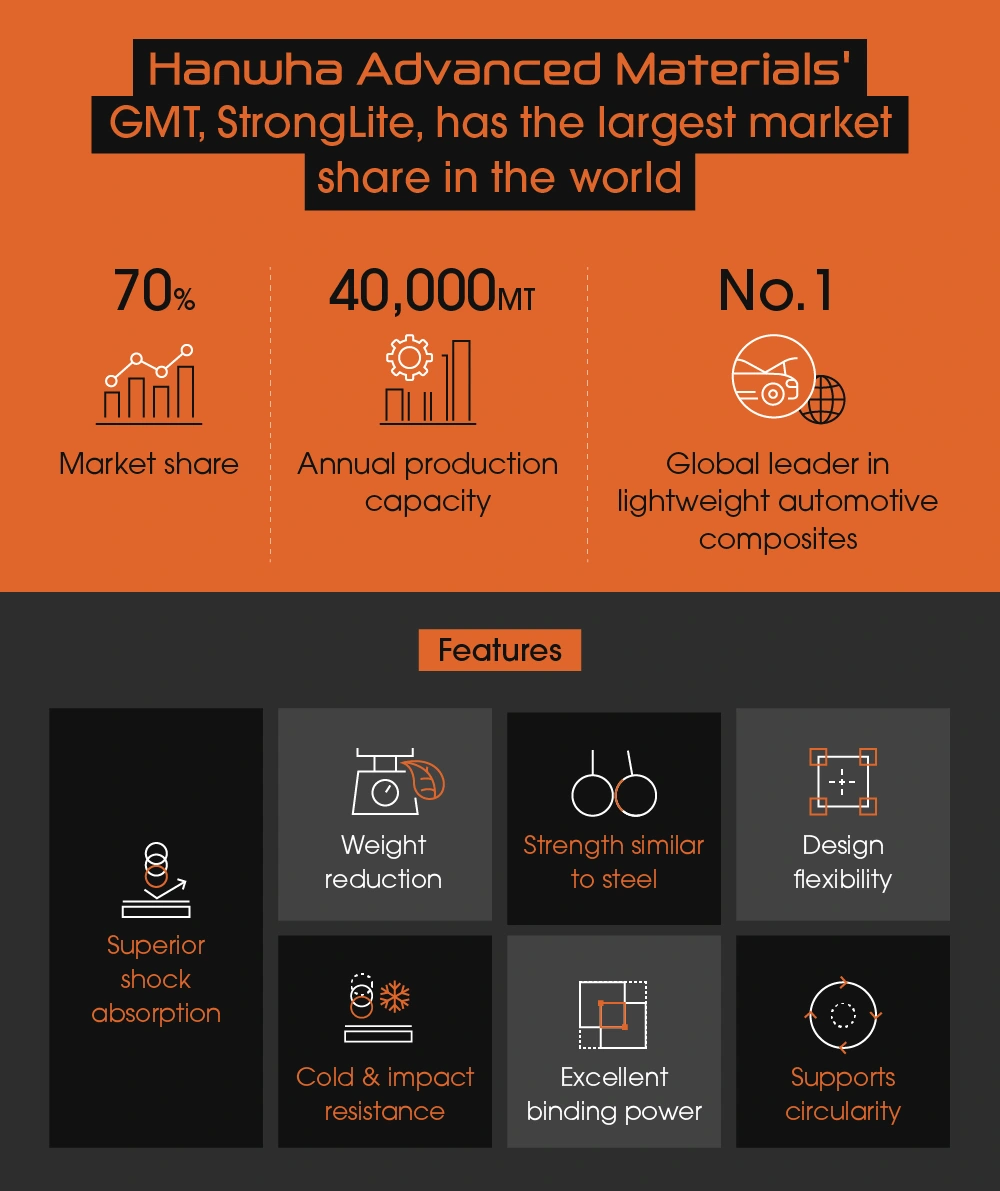

2. Hanwha’s StrongLite dominates the global GMT market

GMT has been around for decades — but few companies have shaped its trajectory like Hanwha. The company began mass-producing GMT under the StrongLite brand in 1995 and has led the global market since 2009. Today, StrongLite accounts for approximately 70% of global GMT supply and boasts the world’s largest production capacity at 40,000 metric tons per year.

Hanwha has supplied StrongLite to major automakers including Hyundai, GM, Volkswagen, Audi, and Honda — a testament to the material’s reliability and scalability. This leadership is supported by decades of R&D, a global supply network, and consistent product performance across high-volume programs.

3. GMT combines strength, flexibility, and manufacturability

EV materials must be strong, durable, and easy to scale — qualities that define advanced thermoplastic composites like GMT. Automakers use it to create high-performance components that are lighter than metal and simpler to manufacture.

Thanks to its compatibility with high-throughput compression molding, GMT can be formed into complex shapes with minimal waste. This flexibility reduces the number of parts required, simplifies assembly, and supports modular platform designs.

The material also holds up under real-world conditions. It absorbs shock, resists corrosion and fatigue, and performs reliably through repeated heating and cooling cycles — making it a natural fit for structural parts in EVs. It also offers strong spring-back force and superior cold resistance — key attributes for crash safety and thermal durability in EV environments.

GMT has also been combined with other materials to enhance its structural performance. In 2013, Hanwha introduced the world’s first hybrid front bumper beam — combining steel and glass fiber mat reinforced thermoplastic (GMT) — expanding its role in critical safety systems.

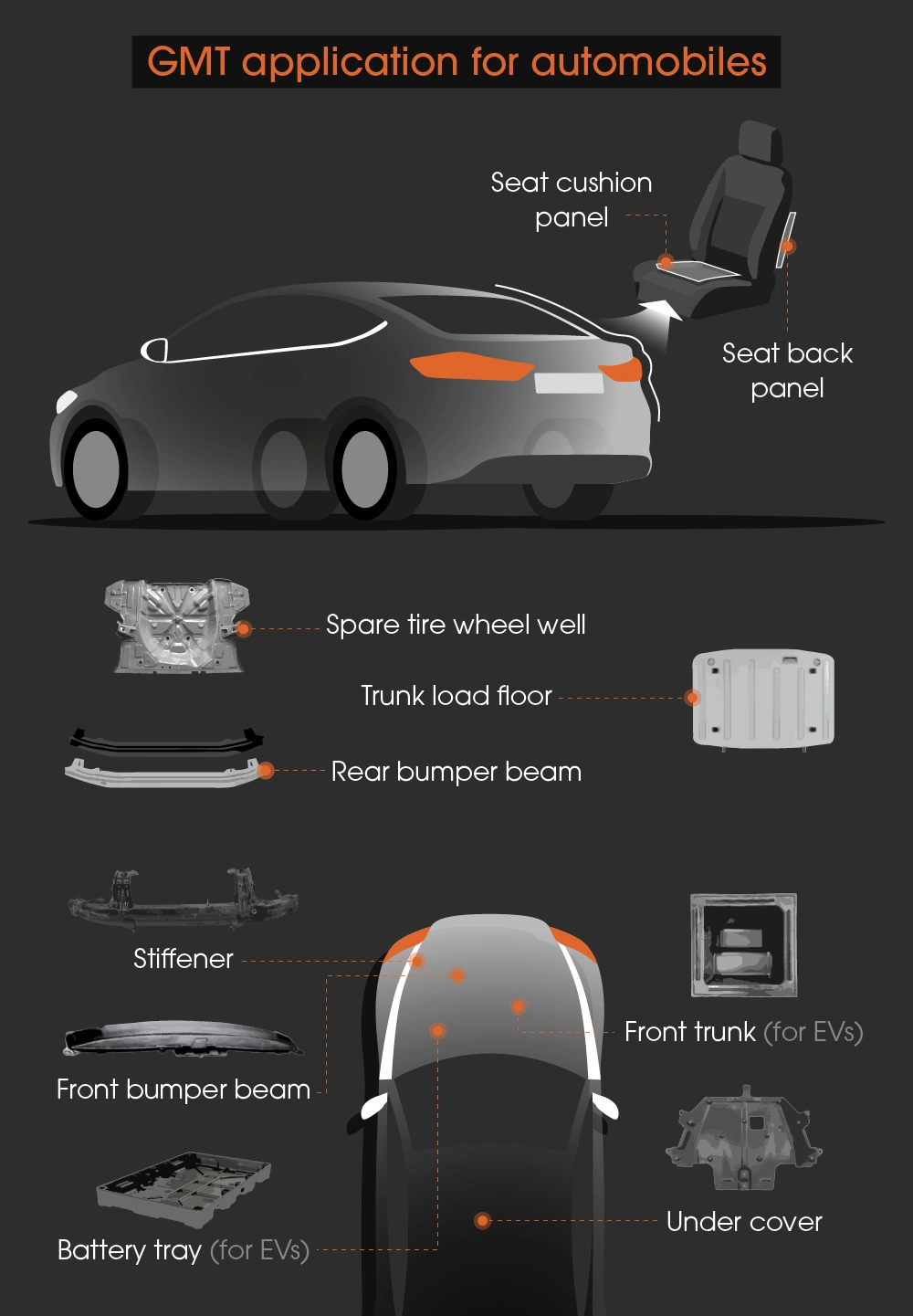

4. From bumper to battery, GMT makes a difference

While it often goes unnoticed, GMT is already used in a range of electric car body parts — including battery trays, underbody shields, rear and front bumper beams, seat backs, and more. Its electrical insulation properties also make it a good fit for high-voltage applications such as EV battery housings.

In the Hyundai Sonata, replacing a steel rear bumper with a StrongLite GMT component reduced its weight by more than 40%, from 4.3 kg to 2.57 kg. For battery trays, GMT can reduce weight by up to 35% compared to steel, helping offset the weight of lithium-ion packs.

These material gains translate into measurable outcomes: better range, improved handling, and higher overall efficiency.

5. GMT supports circularity

Compared to traditional materials like stamped steel or cast aluminum, GMT generally requires less energy to produce — making it more favorable in lifecycle assessments.

These properties make GMT compatible with evolving sustainability mandates — including the EU’s End-of-Life Vehicle Directive — which prioritizes non-toxic, recyclable materials and design-for-disassembly approaches.

StrongLite GMT is certified under the Global Recycled Standard (GRS) and can incorporate up to 20% recycled polypropylene, further enhancing its circularity profile.

GMT offers a more sustainable alternative to many thermoset composites and metals. Hanwha continues to refine its materials portfolio to meet the demands of an increasingly electrified and circular mobility ecosystem.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee